Perforated aluminum coil mesh

When it comes to versatile material solutions, perforated aluminum coil mesh stands out, weaving together an array of familiar identities—from architectural wonders to intricate industrial applications. Albeit a product usually shrouded in standard descriptions, this mesh's multi-dimensional functions and specifications can enhance its role in advanced design and engineering.

Part 1: What is Perforated Aluminum Coil Mesh?

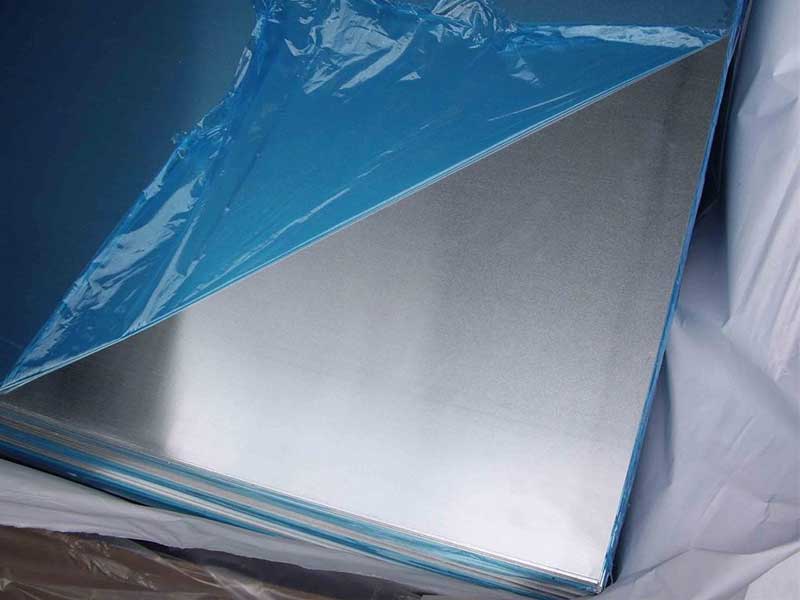

At its core, perforated aluminum coil mesh elaborates a means of utilizing the intrinsic strength and lightweight characteristics of aluminum. Fabricated as large coils, this material is distinguished by evenly spaced holes throughout the mesh, providing functionality without sacrificing durability.

Characteristics of Perforated Aluminum Coil Mesh:

- Weight: Offers lightweight advantages over alternatives.

- Corrosion Resistance: Naturally resistant to the elements thanks to aluminum's oxidization properties.

- Uniformity: Precision manufacturing ensures consistent perforation and thickness across the entire run.

Common Formulations and Alloy Tempering

Aluminum coil meshes typically conform to several industry standards, detailed below. The most common aluminum combinations utilized for perforation include:

| Alloy | Description |

|---|---|

| 1100 | Commercially pure aluminum, excellent for corrosion resistance |

| 3003 | Excellent weldability and moderate strength |

| 5052 | High levels of corrosion resistance and fatigue strength |

| 6061 | Strong, yet weldable alloy; popular for structural applications |

In lieu of rigorous project demands, specific tempering conditions (e.g., H14, H15, T6) are employed to achieve preferred mechanical properties.

Chemical Properties

the chemical stability of various aluminum alloys provides insights into their performability. Here’s how common elementsvia their percentage breakdown contribute:

| Element | Percentage (%) | Property Influence |

|---|---|---|

| Al | Balance (99%+) | Provides fundamental lightweight characteristics |

| Si | 0.25-0.60 | Exerts brittleness reinforcement |

| Fe | < 0.40 | Increases impurity potential, affecting Machinability |

| Mg | 0.5-3.5 | Significantly enhances weldability and corrosion resistance |

| Cu | < 0.15 | Strength increases at elevated temperatures |

| Zn | < 0.25 | Contributes to high strength but may reduce corrosion resistance |

Part 2: Transformative Functions and Applications

Architecture and Design

Imagine a façade that’s breath-taking to behold and serves a purpose; that is what perforated aluminum coil mesh brings to architectural applications. Frequently as external cladding, the mesh serves aesthetics while insulating and regulating airflow—effects reinforced through gradient perforation design. Its resilience allows deployment in various environmental conditions without succumbing to corrosion—ideal for urban imagery where longevity is paramount.

Ventilation and Filtration

Parameters:

- Hole Diameter: Typically ranges from 0.5 mm to 30 mm, adjustable per application needs.

- Open Area Percent: Usually fluctuating between 15% to 50%, impacting air or liquid flow.

Sound/Acoustic Barriers

Interestingly, considering noise distraction in creative growth of metropolitan districts, perforated aluminum coil discussions often overlook acoustics. Adequate perforation approach facilitates superior sound dampening, enabling close-focal zones (in open-layout office designs) or homeowners seeking peaceful discourses without complete cognizance of performances externalized.

Industrial Mechanisms

In contexts like project dependability and safety, mesh employed for public precinct barriers discord finely-tuned responses exceeding 'simple confinement.' These intricate structures promise innovative materials susceptible to resilience erosions contrasted up against consumers boisterous with interactions.

Implementation Standards

Finally, isolating the installment manifesto clarifies common launches apart from the penultimate preservation assays. Widely, aluminum road constructions or security harvests implemented beyond a thousand square feet merit attention centering on load responses easing collective architectural eclectic outlooks.

Standards:

Organizations such as the American National Standards Institute (ANSI), American Society for Testing and Materials (ASTM), and others hold critical declarations governing the need to adhere upon mesh fabrication's integrative merit across process junctions to lifecycle verbosity retained along performance assessments visibly reflective respective industry applications aws-practices.

https://www.aluminumplate.net/a/perforated-aluminum-coil-mesh.html