2024 10mm Thickness Aluminum Plate

Overview

The 2024 aluminum alloy plate in 10 mm thickness is a widely used, high-strength wrought alloy primarily strengthened by copper (Al-Cu system). Known for excellent fatigue resistance, high strength-to-weight ratio, and good mechanical performance at ambient and elevated temperatures, 2024 is a top choice where structural performance and light weight are critical. Typical end uses include aerospace structural components, high-strength fittings, tooling, and performance-oriented fabrication.

Features

- High tensile strength and excellent fatigue resistance.

- Good machinability and surface finish when properly processed.

- Reasonable corrosion resistance when clad (Alclad) or protected; bare 2024 is susceptible to corrosion, especially in marine environments.

- Good fracture toughness in certain tempers (e.g., T351).

- Predictable heat-treatable alloy behavior (precipitation hardening).

- Suitable for precision machining, forming (with limitations), and joining by riveting and certain welding procedures (welding lowers strength in the HAZ).

Chemical Composition (nominal)

| Element | Typical % (wt) |

|---|---|

| Al | Balance |

| Cu | 3.8 – 4.9 |

| Mg | 1.2 – 1.8 |

| Mn | 0.3 – 0.9 |

| Fe | 0.5 max |

| Si | 0.5 max |

| Zn | 0.25 max |

| Ti | 0.15 max |

| Cr | 0.1 max |

| Other | 0.15 each max, 0.05 total (approx.) |

Notes:

- Composition ranges follow common 2024 specifications (e.g., ASTM B209 / AMS 4037 variants). Actual composition should be confirmed from mill certification for critical applications.

Typical Temper/Condition Options

| Temper | Description / Typical Use |

|---|---|

| O | Annealed, maximum ductility; low strength |

| T3 | Solution heat-treated, cold worked, naturally aged; good balance of strength & toughness |

| T4 | Solution heat-treated, naturally aged; lower strength than T6 |

| T6 | Solution heat-treated and artificially aged; maximum strength |

| T351 | Solution heat-treated, stress-relieved by stretching; commonly used for aerospace forgings and plates |

Mechanical Properties (Representative for 10 mm Plate)

Values vary with temper and supplier. Representative values for 2024-T3 / T351 10 mm plate:

| Property | Unit | Typical Value |

|---|---|---|

| Ultimate Tensile Strength (UTS) | MPa | 470 – 520 |

| Yield Strength (0.2% offset) | MPa | 325 – 360 |

| Elongation (A50mm) | % | 10 – 20 |

| Brinell Hardness (HB) | HB | 120 – 150 |

| Density | g/cm³ | 2.78 |

Notes:

- 2024-T6 will show higher UTS and yield; T3/T351 are often specified for better fracture toughness and fatigue resistance.

- Values should be validated by supplier mill test reports for critical design.

Physical and Thermal Properties

| Property | Unit | Value |

|---|---|---|

| Density | g/cm³ | 2.78 |

| Melting Range | °C | 500 – 640 (solidus–liquidus approximate) |

| Thermal Conductivity (room temp) | W/m·K | ~121 |

| Coefficient of Thermal Expansion | 10^-6 /°C | ~23.2 |

| Modulus of Elasticity | GPa | ~73 |

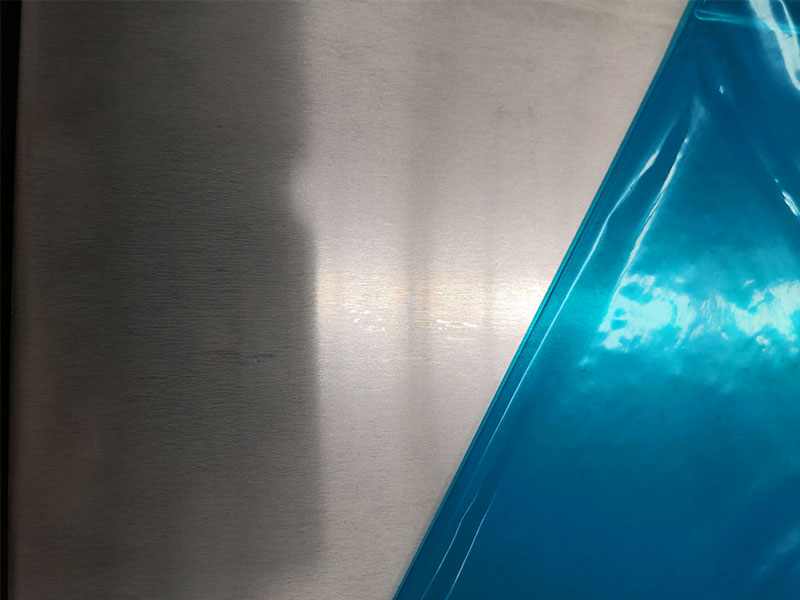

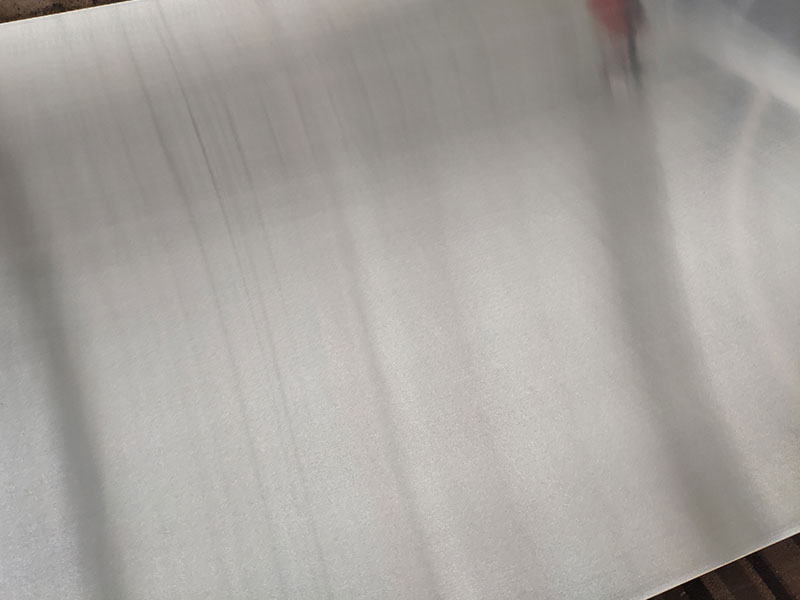

Surface & Finishes

- Mill finish: standard, requires machining or finishing for critical surfaces.

- Alclad: 2024 is often supplied with aluminum cladding to improve corrosion resistance (commonly 2024-Alclad), consisting of a thin high-purity aluminum layer bonded to the core.

- Pre-treated or chemically cleaned for painting/adhesive bonding.

- Anodizing is possible but less common due to copper content; results can vary and color control is limited compared to 5xxx/6xxx alloys.

Manufacturing Forms & Sizes

For 10 mm thickness, common supply forms include cut-to-size plates, sheets, and precision laser/plasma cut blanks.

| Dimension Aspect | Typical Range / Notes |

|---|---|

| Standard thickness | 10.0 mm nominal |

| Maximum plate width | Up to 2000 mm or wider depending on mill |

| Maximum plate length | Mill-dependent; typical up to 8000 mm |

| Tolerances | Thickness tolerances per ASTM/EN standards; confirm with supplier |

| Edge preparation | Sheared, sawn, or milled edges available |

Processing & Fabrication Guidance

- Machining: Good machinability; tool life and surface finish depend on temper. Use sharp tools, appropriate cutting speeds, and flood cooling to avoid built-up edge.

- Forming: 2024 is less formable than 5xxx or 6xxx series. Cold forming possible with springback; warm forming may be used for complex shapes. Consider annealing to O temper if extensive forming is required.

- Heat treatment: Strength achieved by solution heat treating + artificial aging (T6) or natural aging (T3/T4). Heat treatment must follow qualified procedures to meet properties.

- Welding: Fusion welding is generally not recommended for load-bearing applications because welds significantly reduce strength; resistance spot welding and friction stir welding (FSW) are more effective for 2024.

- Joining: Mechanical fastening (riveting, bolting) and adhesive bonding are common; surface pretreatment required for optimal adhesive performance.

- Corrosion protection: Use cladding (Alclad), primers, sealants, or coatings for corrosion-prone environments. Avoid galvanic couples without electrically insulating material between dissimilar metals.

Testing & Quality

- Typical tests: Tensile, hardness, chemical analysis (spectro), intergranular corrosion, fatigue testing for aerospace parts, and nondestructive inspection as required.

- Certification: Mill Test Certificates (MTC) per EN 10204 or equivalent should accompany critical deliveries. For aerospace use, procurement specifications like AMS/QQ, ASTM, or customer drawings will define additional requirements.

Applications

The 2024 alloy 10 mm plate serves in applications requiring high strength with strict weight control and good fatigue resistance:

- Aerospace primary and secondary structures (e.g., wing skins, bulkheads, stiffeners) — often clad (Alclad) for corrosion resistance.

- Structural panels and frames in aircraft and missiles.

- High-performance automotive structural components and chassis parts (limited by corrosion requirements).

- Defense and military platforms where weight and strength are critical.

- Precision machining components: fixtures, tooling plates, and parts requiring high strength-to-weight ratio.

- Sporting goods where high strength and stiffness are desirable (selected parts).

Comparative Notes vs. Other Alloys

| Alloy | Strength | Corrosion Resistance | Formability | Typical Use Cases |

|---|---|---|---|---|

| 2024 | Very high | Moderate (improved with cladding) | Moderate-low | Aerospace structural |

| 6061 | Moderate | Good | Good | General structural, extrusion |

| 7075 | Higher than 2024 | Poor-moderate | Low | High-strength aerospace |

| 5052 | Low-moderate | Excellent | Excellent | Marine, forming |

Ordering & Specification Tips

- Specify temper (T3, T6, T351, etc.) and whether Alclad is required.

- Request mill test certificates showing chemistry, mechanical properties, and heat treatment records.

- Define surface finish and any additional processing (cutting, machining, machining tolerances, edge prep).

- If used in aerospace or safety-critical applications, include procurement spec references (e.g., AMS, ASTM, or customer-specific standards).

- Allow for protective packaging for shipping to prevent extraneous corrosion or mechanical damage.

Storage & Handling

- Store plates flat on pallets or racks in dry, well-ventilated areas away from corrosive agents.

- Use protective interleaving (paper, film) for Alclad surfaces to avoid abrasion.

- Avoid contact with dissimilar metals unless insulated.

Limitations & Cautions

- Not recommended for unprotected use in highly corrosive/marine environments unless clad or coated.

- Welding reduces mechanical strength in the heat-affected zone; use qualified joining methods.

- Lower room-temperature ductility compared to more ductile alloys (e.g., 5xxx series).

| Specification | Value / Note |

|---|---|

| Alloy | 2024 |

| Thickness | 10.0 mm nominal |

| Typical Tempers | T3, T351, T6 |

| Density | 2.78 g/cm³ |

| UTS (T3/T351 typ.) | 470–520 MPa |

| Yield (T3/T351 typ.) | 325–360 MPa |

| Elongation | 10–20% |

| Hardness | 120–150 HB |

| Common Surface | Mill, Alclad |

| Common Forms | Plate, cut-to-size, blanks |

https://www.aluminumplate.net/a/2024-10mm-thickness-aluminum-plate.html