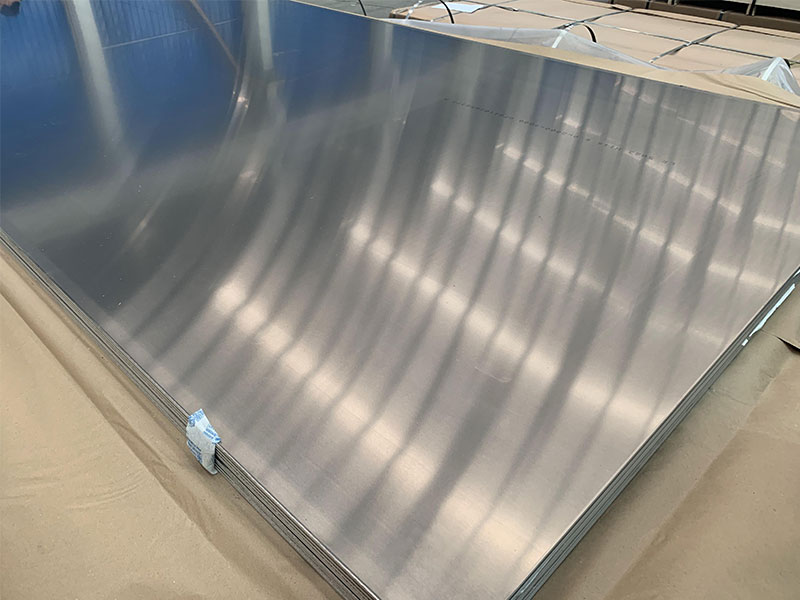

5083 Marine Grade Mirror Finish Aluminium

When we gaze out at the ocean, the surface of the water often reflects a shimmering image, captured tantalizingly within the confines of light. This serene imagery converges beautifully with the stunning characteristics of 5083 Marine Grade Mirror Finish Aluminium, making it an invaluable material in the maritime industry and beyond.

5083 Marine Grade Mirror Finish Aluminium

5083 Marine Grade Aluminium is recognized for its strength, durability, and stunning aesthetics. As an alloy contained primarily of aluminium (Al), magnesium (Mg), and manganese (Mn), it possesses a unique combination of high corrosion resistance, exceptional welding ability, and stable character under extreme conditions often encountered at sea or in industrial environments.

Technical Parameters and Properties

Table of Chemical Properties

| Element | Composition (%) |

|---|---|

| Aluminum (Al) | ≥ 90.0 |

| Magnesium (Mg) | 4.0 - 4.9 |

| Manganese (Mn) | 0.4 - 1.0 |

| Silicon (Si) | ≤ 0.4 |

| Iron (Fe) | ≤ 0.4 |

| Copper (Cu) | ≤ 0.1 |

| Zinc (Zn) | ≤ 0.1 |

A cornerstone of its marine-grade designation is the corrosion resistance conferred by its composition. It withstands electrolytic conditions expertly and is frequently utilized in top-tier shipbuilding and construction projects.

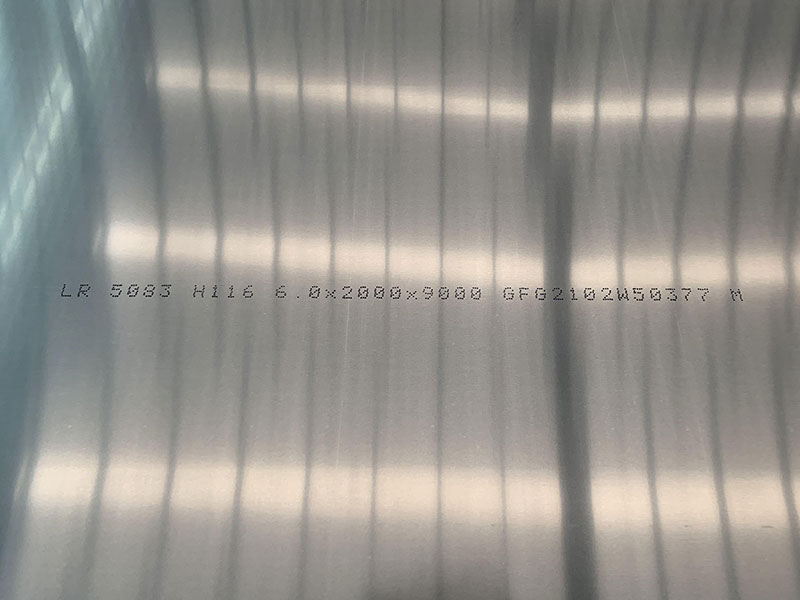

Alloy Tempering

Like fine wine and aged cheese, the characteristics of 5083 encounter sophisticated enhancement during the tempering process. Primarily available in H321 and H116 temper, these conditions amplify tensile strength while optimizing formability, dampening the necessity for a stainless-steel alloy in several applications.

H321: Suited for the hull structure of vessels, including both mega yachts and naval boats, this temper suggests good weldability and formability targets.

H116: Ensures outstanding toughness and corrosion resistance, particularly apt for structural components suffering dynamic conditions (e.g., waves).

Functions and Applications

1. Shipbuilding

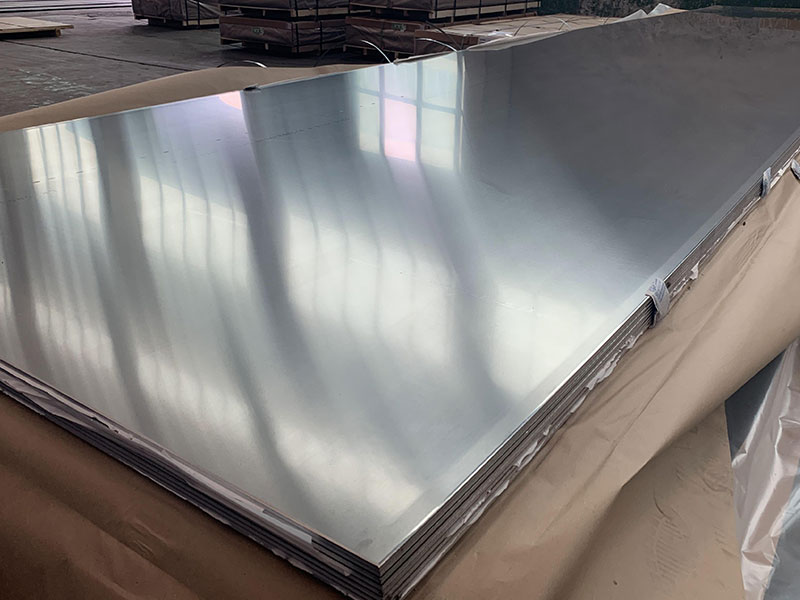

The marriage of aesthetic appeal and resilience becomes vital in commercial and recreational vessels' metallurgical composition. Aluminum's light weight fosters optimal fuel efficiency, while its resistance to rust significantly curtails maritime operational costs.

2. Marine Fabrics and Machinery

Statements are not overstating their significance when it comes to boat fittings and deck hardware. Clan marine environments often ripe with salt water pose corrosion threats. Yet, fabricated 5083 mirror finish panels now cut through this notion–empowering boat builders to architect exceptional components, from hatches and railings to propellers and weight-sensitive stringers.

3. Aerospace Industry Adaptations

Within the aerospace sector, sectors are evolving continuously to demand lighter materials without compromising safety. 5083 Aluminium has found associations where weight savings in critical segments—similarly to that of marine construction—can translate to unprecedented freedom and maneuvering capability while regaining fuel economies.

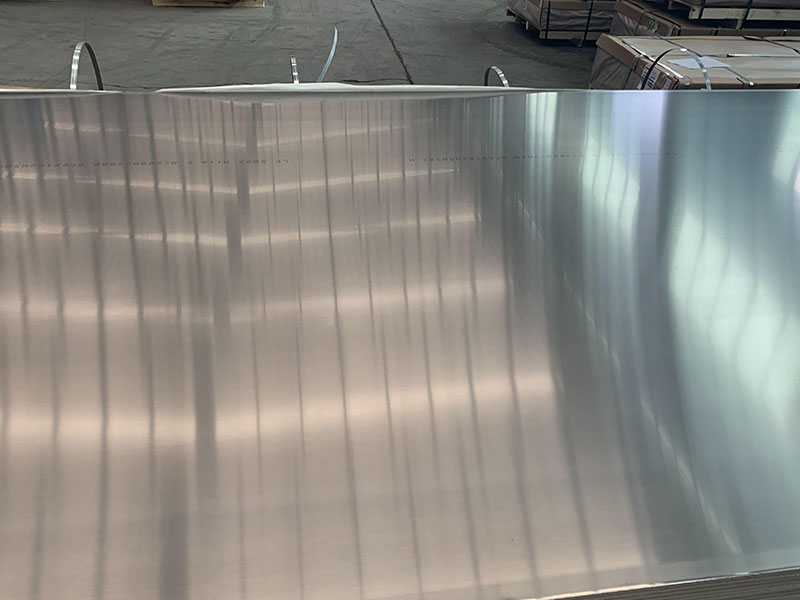

4. Superstructure Support

Reflecting a distinctive surface finish acts as a beacon across the harbors worldwide doesn’t escape marina planners' design philosophy. The mirror finish heightens aesthetic value but resonates through its built-in defense mechanism against sea spray, extending the life cycle with minimum upkeep.

5. Recreational Equipment Ensuring Quality Environmental Interactions

In an age where wellness prioritizes engagements with water—be it skimming along the edges of lakes, rivers, or seas—the implementation of sustainable yet robust leisure conveniences known as paddleboards and high-end rafts exhibit the dexterous capabilities borne by the structural comforts of marine grade mirror finish aluminum reflecting lineage across environmental responsibility.

Implementation Standards

The marine industry rigorously adheres to specific implementation standards to safeguard structures composing maritime and aquatic activities. Marine grade qualifications ensure compliance with *AS/NZS 1665 for Aluminium Welding and AS2270 for Medical/Cosmopolitan Steel Gating, illuminating production metallurgies defined thusly** through hacks deciphering accountability zones in shipbuilding codes.

https://www.aluminumplate.net/a/5083-marine-grade-mirror-finish-aluminium.html