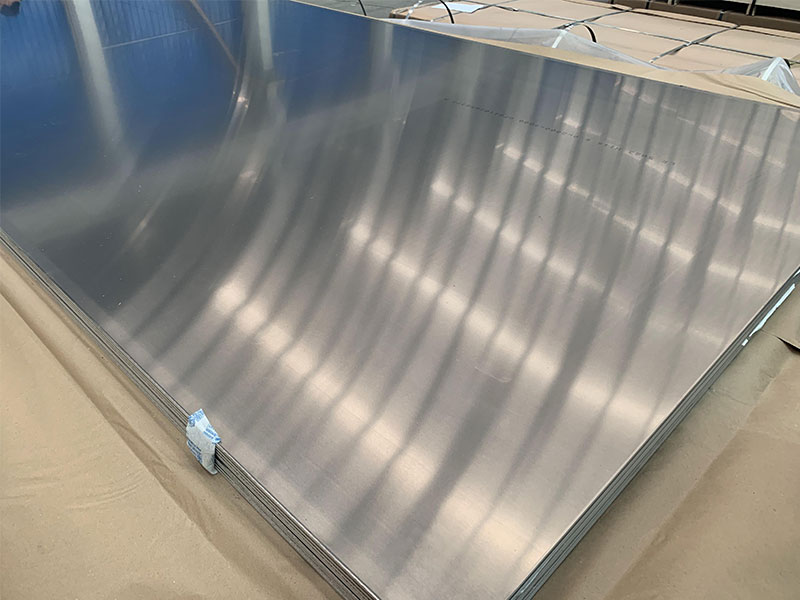

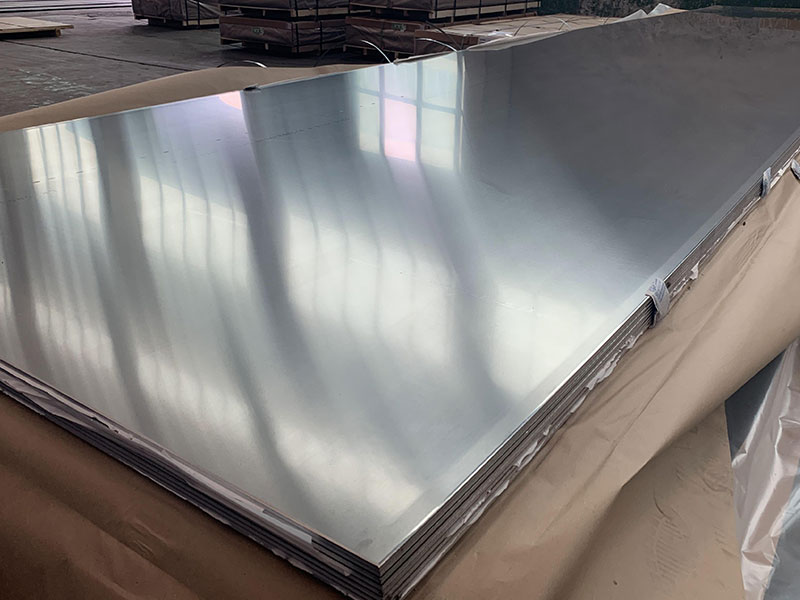

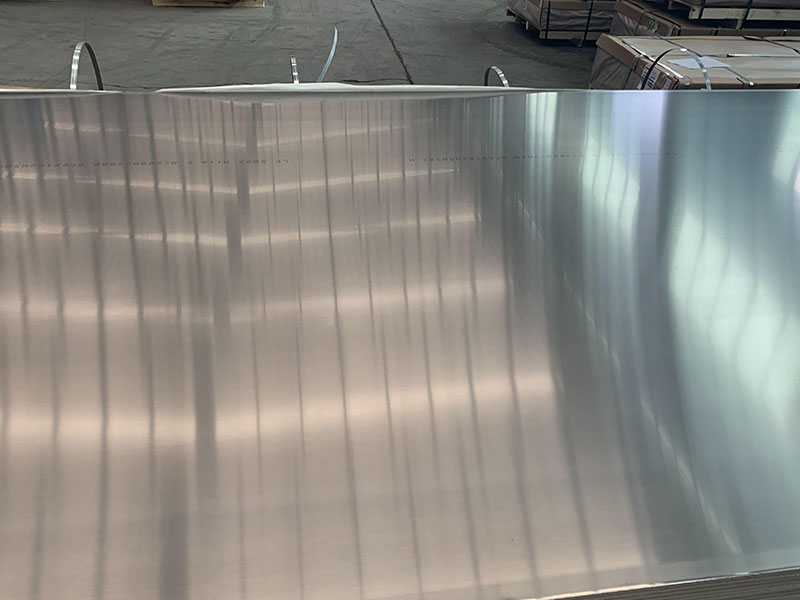

5083 h111 h321 aluminum alloy sheet plate for marine

When it comes to marine applications, selecting the right aluminum alloy sheet plate is crucial for ensuring durability, performance, and safety in harsh ocean environments. Among various options, the 5083 H111 H321 aluminum alloy sheet plate stands out as a material tailor-made for marine use, combining formability, corrosion resistance, and mechanical strength.

In t

What is 5083 Aluminum Alloy?

At its core, the 5083 aluminum alloy is an Aluminum-Magnesium-Manganese series alloy folded perfectly for maritime environments. Magnesium is the primary alloying element that significantly enhances corrosion resistance, particularly resistance to seawater and industrial chemical attacks.

- Series: 5xxx (Aluminum-Magnesium)

- Common form: Plates and sheets used in shipbuilding, offshore, and structural applications

- characteristics: High strength, exceptional corrosion resistance, especially against saltwater, high fatigue strength

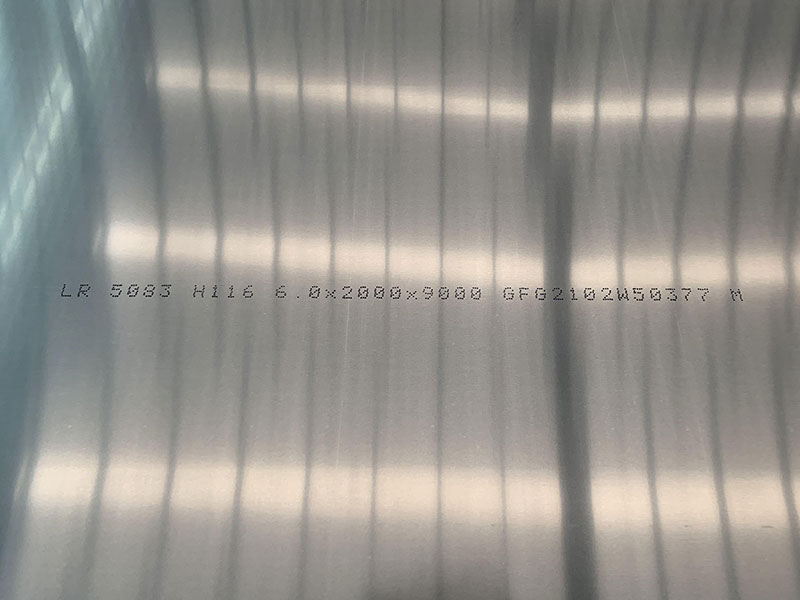

Temper Conditions: H111 vs. H321 in Marine Use

In why 5083 is so valued in marine contexts, we must dig into tempering codes that denote how the material has been processed to achieve certain mechanical properties.

H111 Temper

- Indicates a strain-hardened-annealed condition.

- Material is partially strain hardened, not fully hardened, making it somewhat soft yet stronger than the pure annealed form.

- This temper enhances ductility and allows better forming and welding.

- Commonly used where slight forming (bending or shaping) is necessary.

H321 Temper

- Indicates a temper where the stress-relieved strain hardening has occurred through a low temperature bake after being strain hardened.

- This results in stabilized properties with improved corrosion resistance, mechanical strength (compared to H111), and less residual stress—ideal for more demanding tensile and fatigue resistance.

- Suitable for marine applications with heavy-duty structural demands or where stress resistance is critical.

Properties of 5083 H111 and H321 Aluminum Alloy Sheets

Here’s how different rules benefit marine users practically:

| Property | 5083-H111 | 5083-H321 |

|---|---|---|

| Ultimate Tensile Strength | ~275 MPa | 350-380 MPa |

| Yield Strength | ~145 MPa | 215-285 MPa |

| Elongation at Break | 10%-20% | 10%-15% |

| Corrosion Resistance | Excellent (marine grade) | Excellent (enhanced by temper) |

| Density | 2.66 g/cm³ | 2.66 g/cm³ |

| Thermal Conductivity | ~121 W/m·K (at 25 °C) | ~121 W/m·K |

| Typical Thickness Range | 1.5mm to 500mm | 1.5mm to 200mm |

chemical composition of 5083 aluminum alloy

The chemistry of 5083 alloy controls corrosion protection and weldability essential in marine settings. Typical chemical makeup revealed as follows:

| Element | Composition (wt. %) |

|---|---|

| Magnesium (Mg) | 4.0 - 4.9 |

| Manganese (Mn) | 0.4 - 1.0 |

| Chromium (Cr) | 0.05 - 0.25 |

| Copper (Cu) | ≤0.1 |

| Iron (Fe) | ≤0.4 |

| Silicon (Si) | ≤0.4 |

| Zinc (Zn) | ≤0.15 |

| Titanium (Ti) | ≤0.15 |

| Aluminum (Al) | Balance |

Industry Standards and Implementation

The procurement and utilization of 5083 aluminum alloy plates demand adherence to several industry standards that guarantee authenticity and performance.

- ASTM B209 / B221: Commonly used international specifications for aluminum sheet and plate.

- AMS 4091: Covers sheets and plates made of 5083 with H111/H321 alloys and tempers used in aerospace but frequently referenced for adjoining industries.

- EN 485-2: European norm that defines aluminum alloy chemical composition and mechanical properties, frequently cited in marine structural guidelines.

- ISO 6361 applies particularly to rolled aluminum sheets for pressure vessel fabrication but stands as a useful quality benchmark.

Shipyards and marine fabricators use those referenced standards to secure optimal alloy properties and uniformity for boating or offshore platform projects where safety and longevity are non-negotiable criteria.

Why Is 5083 H111 & H321 Ideal for Marine Use?

1. Heavy Corrosion Resistance

Marine durability requires aluminum that can fend off aggressive environments loaded with salt, moisture, and chlorides. The significant magnesium content in 5083 (4-5%) lets oxide films regenerate quickly on the surface protecting inner bulk so that seawater does not attack newcomer metal substrates.

Also, the stress relieves introduced during H321 temper make it even tougher to corrosive pitting under cyclic stresses aboard ships due to thermal or mechanical loads.

2. Mechanical Robustness with Lightness

Both tempers keep the alloy high strength but benefited differently:

- H111 offers flexibility for parts needing forming without compromising too much strength.

- H321 boosts tensile and yield strength combining superior durability with a good finish required in structural hull plates or superstructure applications, maintaining vital lightweight benefits compared with steel.

3. Excellent Weldability

In fabrication, good welding performance is necessary. The balance of magnesium and minimized copper content drastically reduce welding defects and post-weld degradations inherent to other alloys.

4. Resistance Against Fatigue

Marine vessels demand materials that not only withstand constant waves and movement but also last lifetimes with minimal need for repair or replacement. H321 particularly holds fatigue resistance advantages ideal for load-bearing structural weldments.

Application Examples

- Ship Hulls: Thrives withstanding physical strikes and seawater corrosion.

- Offshore Platforms: Knockout duty for support decks, piping systems.

- Boat Decks and Superstructures: Balancing lightweight and formability.

- Dock and Port Facilities: Anti-corrosion plates for infrastructure in hydrous conditions.

https://www.aluminumplate.net/a/5083-h111-h321-aluminum-alloy-sheet-plate-for-marine.html