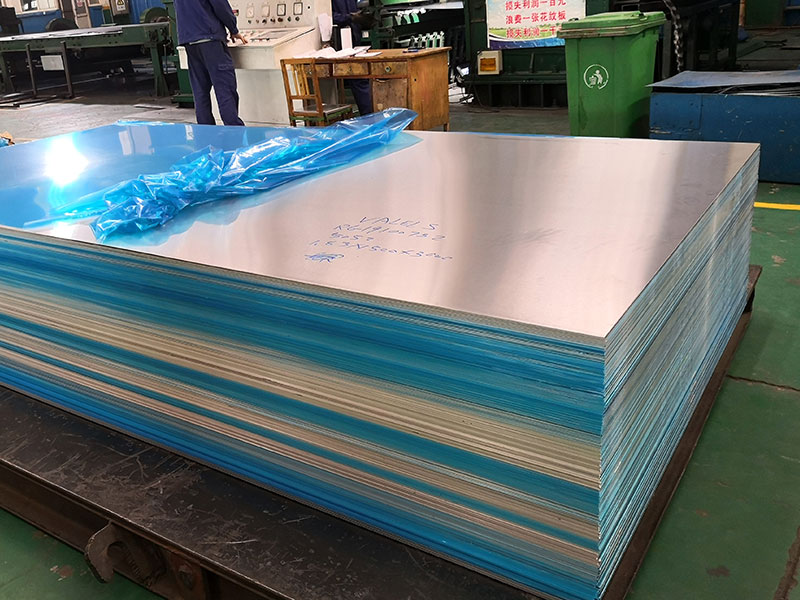

Aluminum sheet 1100 1050 1060 3003 3004 3105

When buyers ask for “just aluminum sheet”, they normally mean cost-effective, easy-to-form, and corrosion-resistant. But those three words can point you to very different alloys: 1100, 1050, 1060, 3003, 3004, 3105.

From a distance, they all look similar: soft, non-heat-treatable alloys, good ductility, often with similar tempers (O/H14/H24, etc.). Up close, each one has its own “personality” and an ideal application range.

Below is a practical, selection-focused view of these alloys—how they behave in real production, why standards and tempers matter as much as chemistry, and where each type usually makes (or breaks) a project.

1. Two Families: 1xxx vs 3xxx Sheets

idea:

- 1xxx series (1100, 1050, 1060) = Nearly pure aluminum: focus on conductivity, deep drawability, and high corrosion resistance, but low strength.

- 3xxx series (3003, 3004, 3105) = Al-Mn alloys: modestly higher strength, still good workability, excellent for general sheet products, building, packaging, and cookware.

1xxx alloys (1100 / 1050 / 1060) – “pure” workhorses

- Aluminum content typically ≥ 99.0–99.6%

- Very soft, very ductile

- Highest electrical and thermal conductivity within commercial wrought alloys

- Excellent corrosion resistance in most atmospheres

- Very easy to form, deep draw, or bend—even in harder tempers

Use when:

- You need formability > strength (lampshades, reflectors, decorative panels)

- You care about conductivity (busbars, transformer windings, heat sinks)

- You need clean surface & corrosion resistance without extra alloying (chemical/tank linings, signage).

3xxx alloys (3003 / 3004 / 3105) – strengthened by Mn

- Aluminum with ~1–1.6% Mn (and small additions of Mg for 3004, Mg/others for 3105)

- 20–60% higher strength than 1xxx in similar tempers

- Still non-heat-treatable (strength controlled by cold working)

- Corrosion resistant and easily formable for most fabrication operations

Use when:

- You want better strength while keeping formability (pan bodies, roofing, vehicle interior panels).

- You need good corrosion resistance for building envelopes & coils (facade, gutters, corrugated sheets, color-coated coils).

- You want performance per cost: 3xxx often replaces 1xxx when some strength margin is needed.

2. Quick Comparison – Mechanical & Application Focus

Typical room-temperature properties (reference range, not guaranteed values)

Representative values in common sheet tempers (thickness 0.3–3.0 mm). Actual specs depend on ASTM/EN/GB and thickness; always check MTC.

| Alloy | Typical Temper | Tensile Strength Rm (MPa) | Yield Strength Rp0.2 (MPa) | Elongation (%, ≈A50) | Notes |

|---|---|---|---|---|---|

| 1050 | O | 60–95 | 15–35 | 25–35 | Very soft, excellent deep-draw |

| 1060 | O | 60–95 | 15–35 | 25–35 | Similar to 1050, slightly higher purity |

| 1100 | H14 | 110–145 | 90–125 | 6–14 | Commercially pure, better hard temper options |

| 3003 | H14 | 130–180 | 115–165 | 5–12 | Workhorse Mn alloy for general sheet |

| 3004 | H34 | 190–240 | 160–215 | 4–10 | Higher strength; classic can body alloy |

| 3105 | H24 | 165–215 | 110–190 | 6–12 | Good for coated sheets, building panels |

patterns:

- For similar tempers, 3xxx alloys clearly outperform 1xxx in strength.

- 1100-O vs 3003-O: 3003 gives noticeably higher strength for nearly the same forming behavior.

- 3004 & 3105 go one step higher in strength vs 3003, targeting more demanding structural or exterior uses.

Representative limits according to common standards like ASTM B209 / EN 573 (values simplified; always refer to current standard for exact limits).

1xxx Series

| Alloy | Si + Fe (max) | Cu (max) | Mn (max) | Mg (max) | Zn (max) | Others (each) | Al (min) |

|---|---|---|---|---|---|---|---|

| 1050 | 0.25 | 0.05 | 0.05 | 0.05 | 0.05 | 0.03 | 99.50 |

| 1060 | 0.25 | 0.05 | 0.03 | 0.03 | 0.05 | 0.03 | 99.60 |

| 1100 | 0.95 (Si+Fe) | 0.05–0.20 | 0.05 | 0.05 | 0.10 | 0.05 | 99.00 |

3xxx Series

| Alloy | Si (max) | Fe (max) | Cu (max) | Mn (%) | Mg (max) | Zn (max) | Others (each) | Al (rem.) |

|---|---|---|---|---|---|---|---|---|

| 3003 | 0.6 | 0.7 | 0.05–0.20 | 1.0–1.5 | 0.05 | 0.10 | 0.05 | Balance |

| 3004 | 0.30 | 0.70 | 0.25 | 1.0–1.5 | 0.80–1.3 | 0.25 | 0.05 | Balance |

| 3105 | 0.6 | 0.7 | 0.30 | 0.3–0.8 | 0.20–0.8 | 0.40 | 0.05 | Balance |

What this chemistry really means in practice:

- Mn (~1%) in 3003/3004: solid-solution strengthening → higher strength with minimal formability sacrifice.

- Additional Mg in 3004/3105: further strength, better response to certain forming, but slightly less ductility than 3003.

- Cu (1100 / 3003 / 3105): small addition to strength and hardness; very low enough not to badly impact corrosion in normal atmospheres.

4. The Role of Temper: Why “H14” or “H24” Matters As Much As Alloy

When customers say “I used 3003 before, but this batch cracks during bending,” the cause is often temper, not the base alloy.

Common tempers for these alloys

- O (Annealed)

- Lowest strength, highest ductility

- Best for deep drawing, complex forming, spinning, high bending depths.

- H12 / H14 / H16 / H18 (strain-hardened, quarter/half/three-quarter/full hard)

- Increased strength via cold working

- Reduced elongation; tighter bend radii become critical.

- H22 / H24 / H26 (strain-hardened and partially annealed)

- Intermediate balance: some cold work + stabilizing anneal

- Very common for coated & roofing applications (e.g., 3003-H24, 3105-H24).

Example pattern (3003 sheet):

- 3003-O: Rm ≈ 90 MPa, excellent deep draw and spin

- 3003-H14: Rm ≈ 140–160 MPa, general forming + roll forming, good for press brakes with proper radius

- 3003-H24: Rm ≈ 150–180 MPa, widely used for color-coated coils and roofing profiles

Rule of thumb:

- Complex forming → “O” or softer “H1x”.

- Profiling / roll-forming / moderate bending → H14 / H24.

- Maximum stiffness in thin gauges with minimal forming → H16 / H18 – but confirm formability.

5.1 1050 & 1060 – Purity first

Distinct advantage:

- Extremely high thermal and electrical conductivity

- Very easy to cold work, deep draw and spin.

Typical applications:

- Electrical:

- Bus bars, cable sheathing

- Transformer windings, power electronics heat sinks.

- Heat transfer:

- Heat exchanger fins, condenser fins, evaporator sheets.

- Surface-critical products:

- Lampshades, sign boards, printed plates, decorative interiors.

- Chemical equipment:

- Tank linings, soft, corrosion-resisting cladding for other alloys.

Implementation notes:

- Often supplied per ASTM B209 / EN 485 for sheet/plate.

- Common tempers: O, H12, H14, H16, H18.

- For tight drawing (e.g., kitchen pans via deep drawing), O-temper is preferable.

5.2 1100 – Commercially pure, a little stronger, widely standardized

Balance of purity, strength and availability.

Typical uses:

- General sheet metal:

- Light reflectors, decorative panels, cladding

- Chemical equipment where heavy loads not present.

- Food & packaging (local regulations permitting):

- Bottle caps, some forms of packaging sheets.

- HVAC and insulation jackets.

Advantages:

- More widely referenced in standards and codes than 1050/1060 in some regions.

- Better availability in large sheet sizes and coils in many markets.

5.3 3003 – The “default” non-heat-treatable sheet alloy

If you do not need welding-strength-critical designs but want reliable, all-around performance, 3003 is often the smartest choice.

Applications:

- Cookware & kitchenware:

- Pans, cookpots (drawn bodies), utensils

- Because of better strength than 1xxx and good anodizing results.

- Building & construction:

- Corrugated sheets, roofing, wall cladding substrates

- Gussets, brackets, interior panels.

- HVAC & refrigeration:

- Ducting, fins, covers, low-stress structural parts.

- Vehicle interior & bodywork:

- Panels, inner door parts, covers.

Processing tips:

- Deep drawing: use 3003-O or soft tempers.

- Painted/coil-coated products: 3003-H24/H26 widely used as substrate.

- Bend radius: plan ≥ 1–1.5 × thickness for H14/H24 to minimize cracking.

5.4 3004 – Thin-gauge strength specialist

3004 is essentially a Mn + Mg version of 3003 with more strength in thin gauges while preserving deep-draw capacity.

Most famous use:

- Beverage can bodies (two-piece cans):

- Requiring high strength, uniform thickness, deep draw and ironing (DDI).

Other uses:

- Thin roofing & cladding where wind load is high.

- Storage tanks, lightweight structural skins requiring higher strength than 3003 in similar thickness.

Processing & standards:

- Often specified in temper H34 / H36 for can stock.

- Directionality and surface cleanliness are critical → you want mills that understand can stock quality (tight flatness, gauge control, earing control).

5.5 3105 – For paint, roofing and exterior finishing

3105 is a “building-skin alloy” in many markets: stronger than 3003 in some tempers, with good forming and excellent reaction to coil coating.

Application focus:

- Pre-painted roofing & walls:

- Color-coated coils and sheets

- Gutter systems, downspouts.

- Roll-formed products:

- Shutters, siding, shelter panels, parapet coverings.

- Sign plates and decorative trims:

- Where color durability and dent resistance matter more than extreme structural load.

Processing tips:

- Needs controlled composition and temper to avoid orange peel during forming after coating.

- Typical temper: H24/H26 before coil coating; after paint-bake, slight additional hardening may occur (bake hardening).

6. Standards & Specification Checklist

When ordering or designing with 1100 / 1050 / 1060 / 3003 / 3004 / 3105 sheets, specifying only “alloy + thickness” is risky. A robust purchase by a professional buyer normally includes:

Alloy & Temper

- e.g., 3003-H14, 1.0 × 1250 mm sheet, ASTM B209

- Or according to EN 485 + EN 573 series in Europe, GB/T 3880 in China.

Thickness & width tolerance, and flatness level

- Critical for roll-forming, laser cutting, precision stamping.

- Request mill-standard tolerances or tighter if required (often at surcharge).

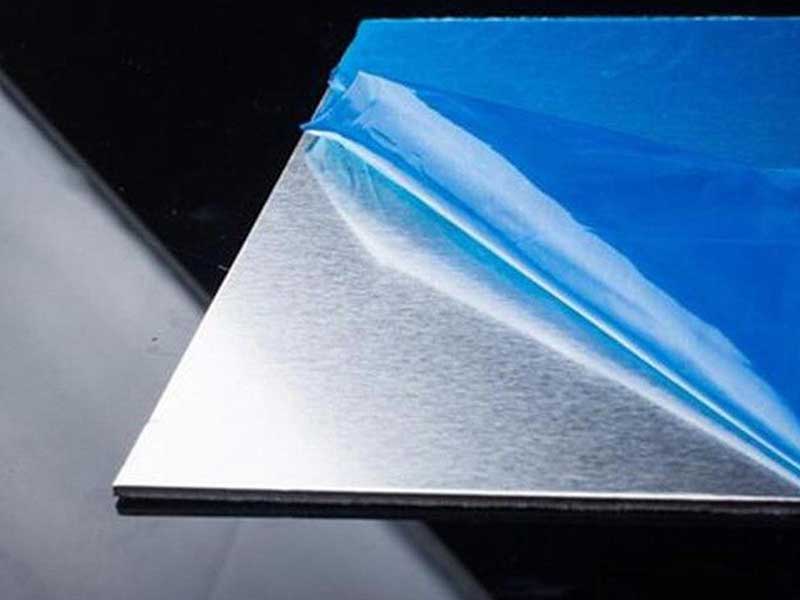

Surface finish & coating

- Mill finish / brushed / embossed / anodizing quality / coating type (PE, PVDF, etc.).

- For anodizing: surface oil, rolling lines and composition homogeneity matter.

Mechanical properties (minimum Rm, Rp0.2, elongation %)

- Referenced to ASTM B209 (North America), EN 485 (EU), GB/T 3880 (China).

- State preference if your forming process is sensitive (deep drawing, spinning).

Inspection and test requirements

- Tensile test, bend test, thickness test, chemical composition verification via spectrometer, ultrasonic or eddy-current tests for special applications.

- For exterior sheets: KG test, gloss, color tolerance (for coated coils).

7. How to Choose Among 1100 / 1050 / 1060 / 3003 / 3004 / 3105

A practical decision path:

Is electrical or thermal conductivity critical?

- YES → go 1050/1060 (or 1100 if mechanical specs/availability better).

- NO → continue.

Is strength a factor?

- Lightly loaded panels, decorative/reflective surfaces, or linings → 1100 is sufficient.

- Need higher stiffness/strength in moderate thickness → focus on 3003 / 3004 / 3105.

Forming severity:

- Deep/double deep drawing, complex spinning:

- 1050-O / 1060-O / 1100-O / 3003-O (pick based on required strength vs cost).

- Moderate press brake bending / roll-forming:

- 3003-H14, 3003-H24, 3105-H24.

- Minimal forming, focus on strength per thickness:

- 3004-H34 / 3105-H26 for thin sheet roofing and facade.

- Deep/double deep drawing, complex spinning:

Surface and finishing:

- High reflectivity, decorative bright finishing, anodizing for appearance:

- 1050 / 1060 / 1100 are typically better base choices.

- Painted building panels & coils:

- 3003 and especially 3105 are common as paint substrates.

- High reflectivity, decorative bright finishing, anodizing for appearance:

Environment:

- Normal indoor/outdoor atmosphere (non-marine, non-strongly alkaline/acidic): all of these are usually safe.

- Marine or chemically aggressive: consider additional protection (thicker coatings, anodizing, or even moving to marine-specific alloys like 5052/5083).

8. Example Matching: Application → Alloy/Temper

- Color-coated roofing coil:

- Usually 3003-H24 or 3105-H24, coil-coated with PE or PVDF.

- Unpainted reflective lamp shades:

- 1060-O or 1100-H14, bright rolled or polished.

- Two-piece beverage can body:

- 3004-H19 can stock (mill-specific temper) with very tight property control.

- Household pan body (deep drawn):

- 3003-O or 1100-O sheet.

- Busbar / heat sink requiring economical conductivity:

- 1050 / 1060 / 1100 in appropriate temper (often H12–H14).

- Gutters and downspouts (painted):

- 3105-H24 with coil coating.

The alloys 1100, 1050, 1060, 3003, 3004, 3105 are often seen as “simple, low-end” aluminum grades. In reality, they cover a wide functionality range—from precision can stock to critical roofing systems and deep-drawn cookware.

To avoid problems and over-costs:

- Start from function: strength, formability, conductivity, surface.

- Select alloy family:

- 1xxx for maximum conductivity and purity.

- 3xxx for better strength and widespread building/packaging usage.

- Lock in temper, standards and tolerances: these determine whether sheet behaves as designed during forming and service.

- Verify with your supplier: demand mechanical test data and chemical analysis; match them to your internal process needs.

https://www.aluminumplate.net/a/aluminum-sheet-1100-1050-1060-3003-3004-3105.html