En aw 2024 t3 aluminium plate

When people search for “EN AW 2024 T3 aluminium plate”, they usually want one of two things:

- high‑strength plate for serious structural work, or

- a drop‑in equivalent to 2024‑T3 for aerospace/engineering projects.

Below is a concise, technical‑but‑plain‑English overview that helps you decide if EN AW 2024 T3 plate is the right material, and what to check before you place an order.

1. What Is EN AW 2024 T3 Aluminium Plate?

EN AW 2024 is a copper‑bearing, high‑strength aluminium alloy, comparable to AA 2024 in the American system.

T3 temper means:

- The plate is solution heat‑treated

- Then cold worked (usually stretched to relieve stress and slightly increase strength)

- Then naturally aged to a stable state

idea: 2024‑T3 is designed for stress‑critical, fatigue‑sensitive parts where strength per unit weight matters more than ultimate corrosion resistance.

Typical applications:

- Aircraft skins and wing structures

- Riveted structures, cleats, fittings

- High‑load brackets, frames, machine components

- Motorsport and racing components

2. Main Characteristics at a Glance

- Very high strength compared to standard 5xxx or 6xxx aluminium

- Good fatigue resistance – suitable for cyclic loading

- Moderate machinability – generally good with proper tooling and coolant

- Not weld‑friendly – welding degrades mechanical properties in the HAZ

- Fair to poor corrosion resistance – often needs cladding, painting or protection

Think of EN AW 2024 T3 as an “aluminium for structural duty” rather than a general‑purpose sheet for decorative or architectural use.

3. Chemical Composition (Typical Values)

EN AW 2024 is an Al–Cu–Mg series alloy. Copper is the main strengthening element.

| Element | Content (%) |

|---|---|

| Cu | 3.8 – 4.9 |

| Mg | 1.2 – 1.8 |

| Mn | 0.3 – 0.9 |

| Fe | ≤ 0.5 |

| Si | ≤ 0.5 |

| Zn | ≤ 0.25 |

| Ti | ≤ 0.15 |

| Others each | ≤ 0.05 |

| Others total | ≤ 0.15 |

| Al | Balance |

Technical note:

The copper + magnesium + manganese system forms hardening phases during solution treatment + aging, giving the 2024 alloy its well‑known high strength.

4. Mechanical Properties – What You Can Expect

Values below are typical, plate products, T3 temper (exact figures depend on thickness and standard).

| Property | Typical Value* |

|---|---|

| Tensile strength Rm | 430 – 480 MPa |

| Yield strength Rp0.2 | 270 – 320 MPa |

| Elongation (A50) | 12 – 20 % (thickness‑dependent) |

| Brinell hardness (HBW) | ~120 – 140 |

| Modulus of elasticity E | ~73 GPa |

| Density | ~2.78 g/cm³ |

*Always confirm with the test certificate of your specific batch and thickness.

5. Standards and Implementation Basis

When you buy EN AW 2024 T3 aluminium plate in Europe or under EN designations, it is usually produced and tested under one or more of these standards:

- EN 573‑3 – Chemical composition of wrought aluminium alloys

- EN 485‑1 / 485‑2 / 485‑4 – Mechanical properties, tolerances and technical conditions for inspection/delivery of plate, sheet and strip

- EN 515 – Temper designations (definition of T3, etc.)

- For aerospace grades: EN 4050 / EN 2139 / EN 2448 and related specs, or OEM aerospace specs (e.g. AIR, AMS)

If you work in aerospace or certified industries, ask explicitly for:

- EN AW 2024 T3 aluminium plate, EN 485‑2 compliant (or specific aerospace standard)

- Mill test certificate (MTC) / 3.1 certificate with chemical and mechanical test values

6. The Meaning of T3 – Why It Matters

The same alloy 2024 can be supplied in different tempers: O, T3, T4, T351, T6, etc.

T3 is distinct because of its processing route:

- Solution heat treatment

- Plate is heated so alloying elements enter solid solution in aluminium matrix.

- Quenching

- Rapid cooling to “freeze” this structure.

- Cold working (strain hardening)

- Stretching or other deformation introduces dislocations, increasing strength and reducing residual stresses.

- Natural aging

- Material rests at room temperature so strengthening phases slowly form, stabilising properties.

Why customers care:

- T3 gives balance: high strength + decent ductility + good fatigue resistance.

- It is the reference condition for many aerospace drawings and historical designs.

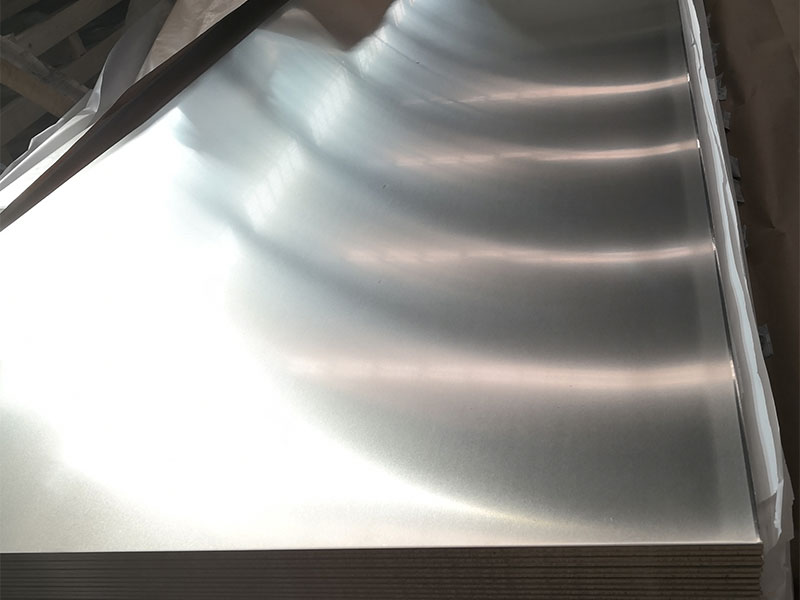

7. Dimensional Range and Common Supply Parameters

Actual dimensions vary by manufacturer, but typical ranges for EN AW 2024 T3 plates are:

- Thickness: approx. 1.0 mm – 150 mm

- Width: up to around 1,250 – 2,000 mm (depending on mill)

- Length: standard 2,000 / 2,500 / 3,000 / 4,000 mm or custom cut

Tolerances are governed by EN 485‑3/4 (or aerospace‑specific tolerances):

- Thickness tolerance: usually ±0.1 mm to ±0.5 mm depending on thickness

- Flatness and squareness: defined by product standard and ordered condition

- Surface condition:

- Mill finish

- Shot‑blasted, brushed, or machined finish on request

- Clad (alclad 2024) possible for improved corrosion resistance in aerospace

8. Processing Behavior – Machining, Forming, Joining

Machinability

- Generally good machinability for a wrought aluminium.

- Use sharp carbide tools, high cutting speeds, suitable coolant.

- Produces continuous chips – use chip breakers for production machining.

Forming

- Fair formability in T3 – can be bent and formed within limits.

- Tight bends, deep drawing or complex shapes may require thinner sections or a softer temper (O or T4) then re‑heat‑treat.

Welding

- Not recommended as a primary welding alloy:

- Susceptible to hot cracking, and

- Properties in weld zone drop sharply

- For structural welding, consider redesign using weldable 5xxx or 6xxx alloys, or use rivets/bolted joints with 2024.

Riveting / Mechanical Joining

- Excellent for riveted and bolted structures – a reason it dominates aircraft applications.

9. Corrosion Behaviour and Surface Protection

Because of its high copper content, 2024 is less corrosion‑resistant than 5xxx or 6xxx series alloys:

- Prone to pitting and intergranular corrosion if unprotected in aggressive environments

- Stress‑corrosion cracking can be a concern in moist or marine surroundings

Common protection strategies:

- Cladding (e.g. 2024‑T3 alclad) – thin pure aluminium layer for improved corrosion resistance

- Anodising – protective oxide layer (thickness depends on environment)

- Painting / Primers – especially on machine parts, aircraft skins

- Regular inspection for fatigue and corrosion on high‑duty components

If you need corrosion performance without external coating, consider 5xxx (e.g. 5083) or 6xxx (e.g. 6061, 6082) instead.

10. How to Choose: When Is EN AW 2024 T3 the Right Plate?

Choose EN AW 2024 T3 aluminium plate when:

- You need weight‑saving plus high strength, often in safety‑critical structures

- Your design relies on well‑known, industry‑standard data and fatigue performance

- Joints are mainly riveted, bolted or mechanically fastened, not heavily welded

- You have a controlled environment and protective coatings to manage corrosion

Consider other alloys when:

- Welding is essential → 5083, 6061, 6082, etc.

- Long‑term, uncoated outdoor or marine exposure is critical → 5xxx series

- You want excellent corrosion resistance with moderate strength → 5xxx or 6xxx

11. What to Specify When Ordering

To avoid mismatches, include these points in your enquiry or purchase order:

- Alloy & temper:

- “EN AW 2024 T3 aluminium plate”

- Standards:

- “According to EN 573‑3, EN 485‑1/2/4”

- Plus aerospace standard if required

- Dimensions & tolerances:

- Thickness × Width × Length + any special flatness requirements

- Surface condition:

- Mill finish / machined / cladded (Alclad) / protected foil

- Certification:

- 3.1 material certificate with chemical composition and mechanical test results

- End use (optional but helpful):

- Aerospace structure / tooling plate / general engineering, etc. – helps the supplier select the most suitable route.

https://www.aluminumplate.net/a/en-aw-2024-t3-aluminium-plate.html