Ribbed aluminium sheet

Ribbed aluminium sheet (also known as corrugated, profiled, or fluted aluminium sheet) is a lightweight, high‑strength sheet product engineered with parallel ribs or waves on its surface. These ribs increase stiffness, improve load‑bearing performance, and enhance slip resistance, making the material ideal for architectural, industrial, and transport applications.

This guide provides a concise but detailed overview of ribbed aluminium sheet, including composition, performance, technical specifications, and typical use cases.

1. Features at a Glance

- High stiffness‑to‑weight ratio thanks to ribbed profile

- Excellent corrosion resistance in outdoor and industrial environments

- Good formability and workability for bending, cutting, and punching

- High slip resistance in flooring and walkway applications

- Attractive appearance with clear linear profiles, suitable for visible façades

- Easy handling and installation due to low density and manageable sheet sizes

- Recyclable and sustainable, with low maintenance costs over service life

2. Common Alloys & Chemical Composition

Ribbed aluminium sheets are produced from several wrought alloys, selected based on required strength, corrosion resistance, and forming behavior. Typical alloys include:

- 1xxx Series (e.g., 1050, 1100): Very high purity, soft, excellent corrosion resistance and formability

- 3xxx Series (e.g., 3003, 3004): Manganese‑alloyed, moderate strength, very good corrosion resistance

- 5xxx Series (e.g., 5005, 5052, 5754): Magnesium‑alloyed, higher strength, excellent corrosion and marine resistance

Typical Chemical Composition Ranges (wt%)

Note: Actual composition depends on specific alloy and standard (EN, ASTM, GB, etc.). Values below are representative.

| Alloy | Si (%) | Fe (%) | Cu (%) | Mn (%) | Mg (%) | Cr (%) | Zn (%) | Ti (%) | Al (approx.) |

|---|---|---|---|---|---|---|---|---|---|

| 1050 | ≤0.25 | ≤0.40 | ≤0.05 | ≤0.05 | ≤0.05 | – | ≤0.05 | ≤0.03 | ≥99.50 |

| 1100 | ≤0.95* | – | 0.05–0.20 | ≤0.05 | – | – | ≤0.10 | – | Balance |

| 3003 | ≤0.60 | ≤0.70 | ≤0.20 | 1.0–1.5 | – | – | ≤0.10 | – | Balance |

| 5005 | ≤0.30 | ≤0.70 | ≤0.20 | ≤0.20 | 0.50–1.1 | – | ≤0.25 | ≤0.20 | Balance |

| 5052 | ≤0.25 | ≤0.40 | ≤0.10 | ≤0.10 | 2.2–2.8 | 0.15–0.35 | ≤0.10 | ≤0.10 | Balance |

| 5754 | ≤0.40 | ≤0.40 | ≤0.10 | 0.30–0.50 | 2.6–3.6 | – | ≤0.20 | ≤0.15 | Balance |

* Combined Si + Fe

For ribbed sheets used in structural cladding, vehicle flooring, and marine environments, 5xxx series alloys (e.g., 5754, 5052) are common for their strength and corrosion resistance.

3. Mechanical & Performance Characteristics

Mechanical properties vary with alloy, temper, and sheet thickness. Ribs significantly improve bending stiffness, allowing thinner sheets to carry similar loads to thicker flat sheets.

Typical Mechanical Properties (Representative Values)

| Alloy / Temper | Tensile Strength Rm (MPa) | Yield Strength Rp0.2 (MPa) | Elongation A50 (%) | Density (g/cm³) |

|---|---|---|---|---|

| 1050 H14 | 95–125 | 75–105 | 4–10 | 2.70 |

| 3003 H14 | 145–185 | 120–160 | 5–10 | 2.73 |

| 5005 H34 | 145–190 | 110–160 | 3–8 | 2.70 |

| 5052 H32 | 210–260 | 130–180 | 7–12 | 2.68 |

| 5754 H22 | 215–265 | 130–190 | 8–12 | 2.67 |

Functional Performance

| Performance Aspect | Description |

|---|---|

| Bending stiffness | Ribs increase moment of inertia, improving stiffness vs. flat sheet |

| Load‑bearing capacity | Higher capacity for distributed loads in roofing and flooring |

| Slip resistance | Ribbed surface reduces risk of slipping in wet or oily conditions |

| Corrosion resistance | Natural oxide film; excellent in atmospheric and marine environments |

| Thermal expansion | Similar to flat aluminium; ribs improve dimensional stability under load |

| Fire behavior | Non‑combustible; melts without releasing toxic fumes |

| Acoustic behavior | Ribs help break up sound reflections; can be combined with insulation |

4. Technical Specifications

Dimensions, profiles, and tolerances can be customized. The following ranges are typical for commercial ribbed aluminium sheet.

Dimensional Range

| Parameter | Typical Range | Notes |

|---|---|---|

| Thickness (base metal) | 0.5 – 3.0 mm | Thin gauges for roofing; thicker for flooring |

| Overall width | 600 – 1500 mm | Dependent on profile and coil width |

| Length (cut sheet) | 1000 – 12000 mm | Custom lengths to reduce on‑site cutting |

| Rib height | 5 – 50 mm | Higher ribs for structural roofing/walls |

| Rib pitch (spacing) | 50 – 250 mm | Optimized for stiffness and aesthetics |

| Profile type | Trapezoidal / sinusoidal / custom | Determined by application and load requirements |

Profile & Tolerance Data (Typical)

| Item | Value / Standard |

|---|---|

| Thickness tolerance | ±0.05–0.10 mm (depending on thickness) |

| Width tolerance | ±2.0 mm |

| Length tolerance | ±3.0 mm (cut‑to‑length) |

| Straightness | ≤1.5 mm/m |

| Edge condition | Mill edge or trimmed |

| Surface finish (mill) | Ra 0.4–1.2 µm (typical range) |

| Coatings (optional) | PE, PVDF, anodizing, powder coating |

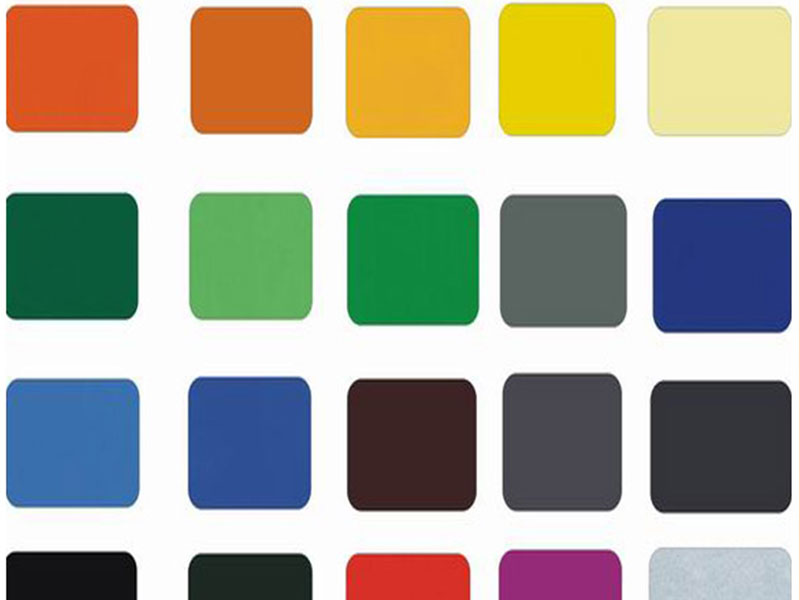

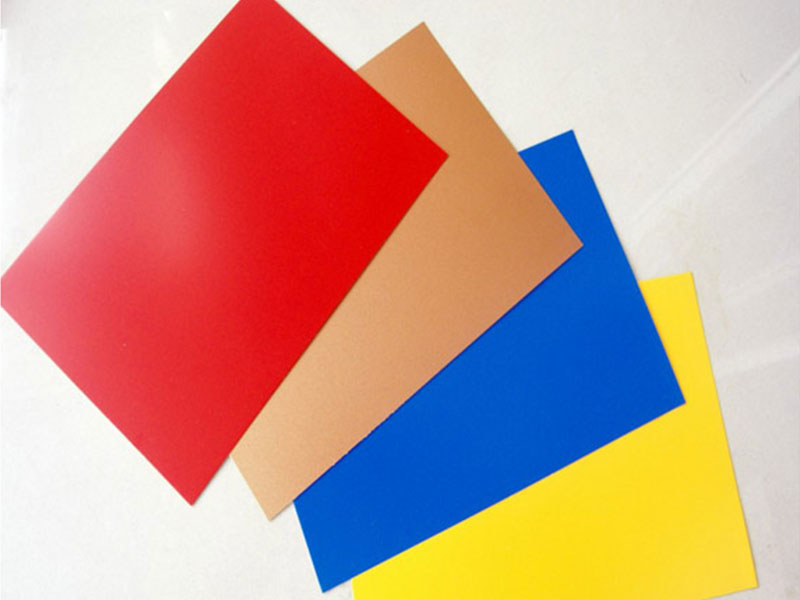

5. Surface Finishes & Coatings

Ribbed aluminium sheets can be supplied either with mill finish or with decorative/functional coatings.

| Finish / Coating | Benefits | Typical Use Cases |

|---|---|---|

| Mill finish | Cost‑effective, good corrosion resistance | Industrial plants, non‑visible areas |

| Anodized | Hard surface, improved wear and corrosion resistance, colorable | Architectural façades, interior design |

| Painted (PE) | Broad color range, good UV resistance | Roofing, wall cladding in standard climates |

| Painted (PVDF) | Superior UV and chalk resistance, long‑term color stability | Premium façades, coastal projects |

| Powder coated | Tough, thick coating, good impact resistance | Railings, balcony floors, equipment covers |

6. Applications

Ribbed aluminium sheet is versatile and widely used across construction, transportation, and industrial sectors.

6.1 Building & Construction

- Roofing and wall cladding

- Industrial halls, warehouses, agricultural buildings

- Commercial and residential roofing systems

- Soffits and ceilings

- Rifled linear appearance for modern architectural designs

- Balcony and terrace decking

- Anti‑slip and corrosion‑resistant, easy to clean

- Walkways, platforms, and stair treads

- In plants, refineries, and power stations

6.2 Transportation

- Truck and trailer flooring

- Ribbed surface for grip, lightweight for fuel savings

- Bus and train interiors

- Slip‑resistant floors, durable and easy to maintain

- Shipbuilding and offshore structures

- Deck panels and access platforms in marine environments

6.3 Industrial & Commercial

- Machinery covers and guards

- Lightweight panels with enhanced rigidity

- Cold storage and HVAC enclosures

- Good thermal properties and corrosion resistance

- Ramps and loading docks

- Anti‑slip, abrasion‑resistant surfaces

7. Benefits for End Users

7.1 Structural & Operational Benefits

- Weight reduction compared with steel or thicker flat sheets

- Lower dead load on building structures

- Easier handling, lifting, and installation

- Higher stiffness per unit weight

- Ribbing geometry improves panel span capability

- Reduced support structure costs

- Greater spacing between purlins or sub‑girders may be possible

7.2 Durability & Maintenance

- Long service life in harsh climates and coastal regions

- Minimal maintenance

- Periodic cleaning typically sufficient

- No rusting, chipping, or spalling like some coated steels

- Excellent recyclability

- High residual value at end of life

7.3 Safety & Comfort

- Improved slip resistance

- Safer access routes and working platforms

- Fire‑safe

- Non‑combustible, no toxic smoke generation from the metal itself

- Acoustic and thermal flexibility

- Works well with insulation systems behind the profiled sheet

8. Selection Guidelines

When choosing ribbed aluminium sheet, consider the following:

| Design Factor | Recommendation / Consideration |

|---|---|

| Environment | 5xxx series for marine/industrial; 3xxx or 1xxx for mild atmospheres |

| Mechanical loads | Select thickness and rib profile according to span and design load tables |

| Aesthetics | Choose profile geometry (trapezoidal/sinusoidal) and coating/color |

| Forming requirements | Softer tempers (H22, H24) for complex forming; harder tempers for strength |

| Joining method | Compatibility with mechanical fasteners, rivets, or adhesive bonding |

| Regulatory standards | Check compliance with EN, ASTM, or local building codes |

| Category | Typical Value / Range |

|---|---|

| Alloys | 1050, 1100, 3003, 5005, 5052, 5754 |

| Tempers | O, H12, H14, H22, H24, H32, H34 |

| Thickness | 0.5–3.0 mm |

| Standard width | 600–1500 mm |

| Sheet length | 1000–12000 mm (custom) |

| Rib height | 5–50 mm |

| Surface finishes | Mill, anodized, PE/PVDF coated, powder coated |

| Standards | EN 485 / EN 573, ASTM B209, or equivalent |