UV CTCP Plate Offset Positive CTP Plates

In the constantly evolving world of printing technology, innovations integrating materials science and imaging techniques have paved the way for dramatically improved performance, durability, and print quality. One such advancement — the UV CTCP Plate Offset Positive CTP Plates — represents a seamless convergence of UV-sensitive chemistry and the robustness of aluminum alloy substrates, offering an solution for offset printing workflows.

UV CTCP Plates in Offset Printing

CTCP (Computer-to-Plate) technology revolutionized offset printing by eliminating intermediate films, directly transferring digital artwork to aluminum plates used in printing presses. UV CTCP plates incorporate ultraviolet (UV) light-activated photopolymer coatings on an aluminum base. Once exposed to UV light and developed chemically, the photopolymer delineates the image areas to accept ink, effectively creating the printing face.

advantages of this UV-sensitive lamination include higher resolution, faster plate making, longer run life, and eco-friendliness owing to less chemical waste.

Positive-Working CTP Plates: How They Function

CTP plates come in two major categories: positive-working and negative-working, distinguished by how they respond to exposure.

- Positive-working plates: The exposed areas become soluble during development and wash away, leaving behind the non-exposed areas that carry ink.

- Negative-working plates: Exposed regions harden and remain, whereas unexposed areas wash off.

Using positive-working UV CTCP plates has several intrinsic benefits, among them a finer image quality due to less swelling of polymer, better chemical stability, and more predictable development processes.

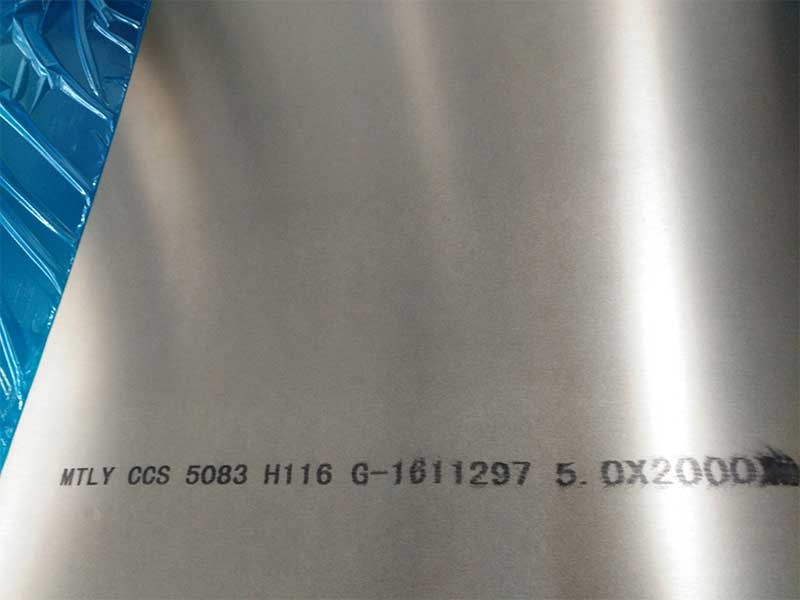

The Aluminum Base Plate: Alloy Selection and Tempering

At the heart of UV CTCP plates lies a precisely engineered aluminum alloy base, crucial for mechanical stability and performance consistency. The typical base uses aluminum alloy 1050 or 3003, both known for excellent corrosion resistance, flatness, and surface polishability. For enhanced strength and flatness:

- Alloy: 1050 (minimum 99.5% aluminum), prized for high purity and superior surface finish

- Temper: H14 (strain-hardened and partially annealed) – balanced to achieve rigidity without brittleness

- Thickness: commonly 0.30mm - 0.40mm, optimal for consistent stiffness and minimal heat expansion distortion during plate making

These plates undergo precision brushing and anodizing processes that achieve a micro-rough surface topology, encouraging strong bonding with UV-sensitive coatings and resisting press-caused wear.

| Parameter | Typical Value | Unit | Remarks |

|---|---|---|---|

| Alloy | 1050 or 3003 | - | High purity aluminum alloys |

| Temper | H14 | - | Strain-hardened, controlled softness |

| Thickness | 0.30 - 0.40 | mm | Thickness suited for offset CTP |

| Anodic Layer | 8 - 12 | microns | Enhances longevity and adhesion |

| Roughness (Ra) | 0.15 - 0.25 | microns | Microscopic surface texture for coating adherence |

UV-Curable Photopolymer Coating

The coatings applied to aluminum plates for UV CTCP processes leverage acrylate-based photopolymers sensitized to specific UV wavelengths (typically 350-420 nm). This photopolymer is chemically bonded to the anodized aluminum surface, ensuring durability on the press while offering:

- Low exhaustion during printing

- Resistance to chemical solvents during plate development

- Flexibility during thermal cycling caused by press heat and exposure

Implementation Standards and Industry Compliance

Globally, CTP plate manufacturing meets strict standards for compatibility and interoperability. Prime among them:

- ISO 12647-2:2013 – Process control for printing

- ASTM F2501 – Test method for lithographic printing plates under a variety of production conditions

- RoHS Directive 2011/65/EU – Chemicals and heavy metal restriction safeguarding environment and operators

Manufacturers certify positive-working UV CTCP plates against these standards, guaranteeing quality prints that last for upwards of 100,000 impressions in typical commercial runs.

Unique Advantages of UV CTCP Plate Offset Positive Plates

- Enhanced Image Sharpness: The positive-working chemistry limits swelling and deformation at the edges of image areas, greatly improving detail fidelity.

- Long Run Life: Optimized alloys coupled with UV-cured polymer coatings resist abrasion from ink and fountain solutions.

- Environmentally Considerate Process: Less chemical developer is consumed in positive-working plate development, mitigating hazardous waste.

- Faster Plate Production: UV exposure combined with digital CTP workflows reduce pre-press turnaround times.

- Plate-Press Harmony: Thermally stable aluminum alloys minimize vibration or distortion on the press.

https://www.aluminumplate.net/a/uv-ctcp-plate-offset-positive-ctp-plates.html