1.5 aluminum sheet

When it comes to choosing materials for industrial, architectural, or DIY projects, aluminum sheets often top the list due to their practicality, strength, and aesthetic appeal. Among the various thickness options, 1.5 aluminum sheet holds a special niche.

What Exactly is a 1.5 Aluminum Sheet?

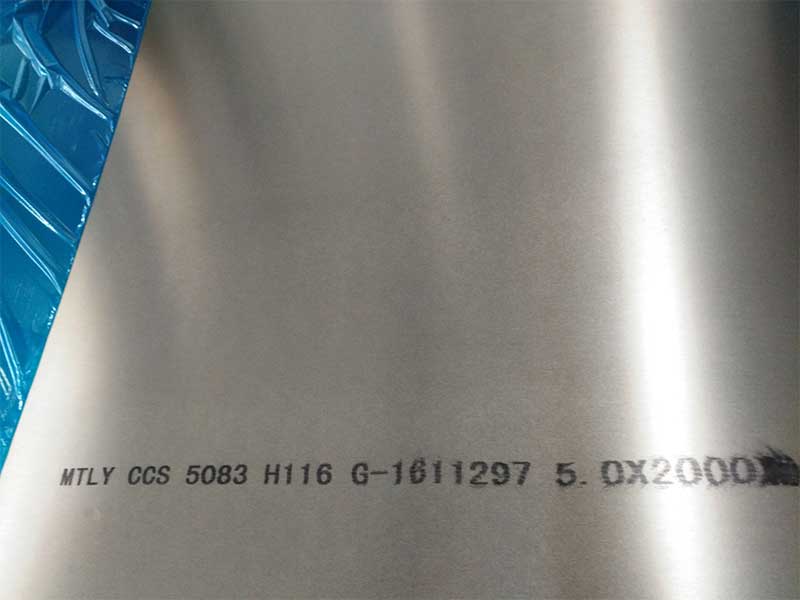

The term 1.5 aluminum sheet simply refers to aluminum alloy sheets that are 1.5 millimeters thick. This thickness strikes an excellent balance — offering sufficient rigidity while maintaining a lightweight nature. This thickness is commonly used in applications ranging from automotive panels, aerospace components, signage, to decorative architecture as it delivers versatility without excess bulk or cost.

the Parameters and Specifications

Physical Parameters:

| Parameter | Value |

|---|---|

| Thickness | 1.5 mm |

| Width Range | Typically 1000mm-2000mm (varies by supplier) |

| Length | Customizable, often 2000mm upwards |

| Density | Approximately 2.7 g/cm³ (all standard aluminum) |

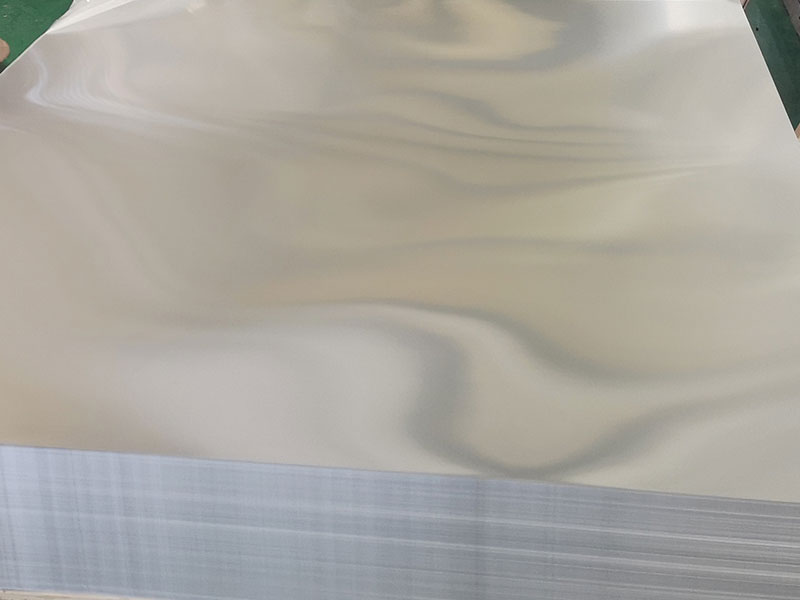

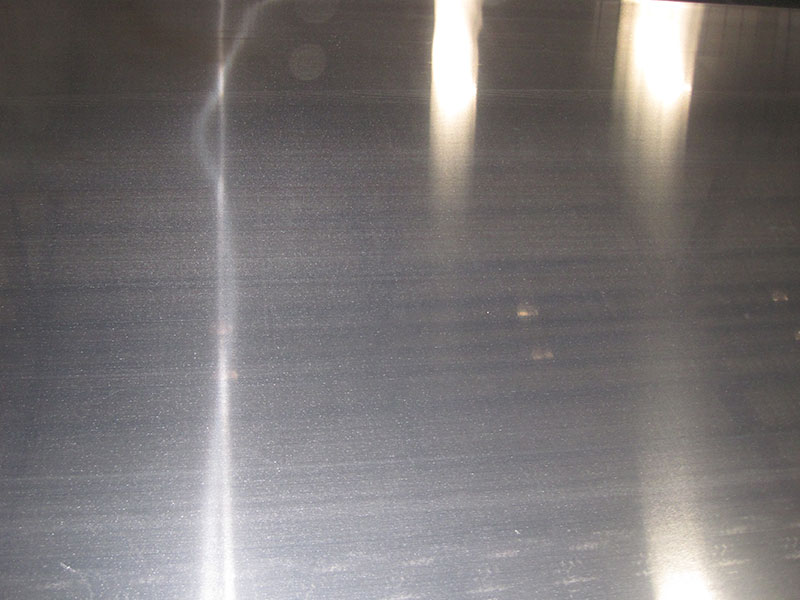

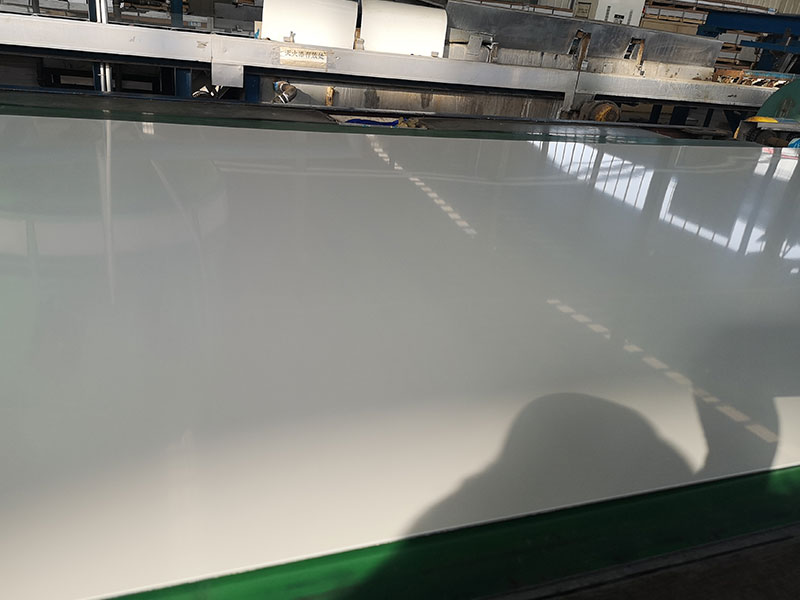

| Surface Finish | Mill finish, anodized, brushed, or coated |

| Tensile Strength | 110-300 MPa (example range, depends on alloy & temper) |

Note: Thickness is integral to structural stability and machinability for aluminum sheets. At 1.5mm, it provides considerable resilience suitable across many sectors.

Implementation Standards of 1.5 Aluminum Sheet

- ASTM (American Society for Testing and Materials) standards such as ASTM B209 specify the requirements and technical properties for aluminum and aluminum-alloy sheet and plate products.

- EN Standards like EN 485 dictate mechanical properties, tolerances, and other manufacturing regulations predominantly active in Europe.

- Industry standards focus on dimensions, tolerances, microstructural homogeneity, surface characteristics, and strength in conformity with the alloy and temper.

Using 1.5 aluminum sheets manufactured under strict implementation standards guarantees consistency in quality and durability.

Common Alloy Types and Temper Designations

Aluminum sheets are usually alloyed to enhance strength, corrosion resistance, or machinability:

| Alloy Series | Common Uses/Features | Temper Types |

|---|---|---|

| 1xxx Series (e.g., 1050, 1100) | Excellent electrical conductivity, corrosion resistance, soft and pliable (commercially pure) | O (annealed), H14 (strain hardened) |

| 3xxx Series (e.g., 3003) | Good corrosion resistance, moderate strength, widely used for outdoor roofing and siding | H14, H16 |

| 5xxx Series (e.g., 5052) | High strength, excellent corrosion resistance, used in marine, automotive, and structural terms | H32, H34 |

| 6xxx Series (e.g., 6061, 6082) | Good strength and corrosion resistance; alloyed with magnesium and silicon, ideal for structural applications | T6 (solution heat treated & artificially aged), T5 |

At 1.5mm thickness, especially 5052-H32 and 6061-T6 sheets are exceedingly popular across various industries owing to their mechanical robustness.

Tempering (Heat Treatment) of 1.5 Aluminum Sheets

Temper designation defines the method by which aluminum measuring houses improve mechanical properties—like tensile strength and hardness—through controlled heating and mechanical deformation.

- O temper: Full annealing to maximize ductility. Useful for intricate bending or forming on 1.5mm thin sheets.

- H temper: Work hardened to various degrees—H14 (quarter hard), H18 (full hard) are common on light gauges for improved stiffness.

- T temper: Heat treated to set the material in a specific strength profile, i.e., T6 for peak strength.

Selecting the correct temper depends on the final application requirements—in roadsigns, rivets, or fabrication where stiffness matters, stronger T-tempers like T6 paired with 1.5 mm thickness exceed simple utilities.

Chemical Composition of Popular Aluminum Alloys at 1.5 mm

Here's a basic chemical breakdown of common 1.5mm sheet alloys, expressed in weight percentages:

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Al (Balance) |

|---|---|---|---|---|---|---|---|---|---|

| 1050 | 0.25 max | 0.40 max | 0.05 max | 0.05 max | 0.03 max | 0.03 max | 0.05 max | 0.03 max | >99.5 |

| 3003 | 0.6 max | 0.7 max | 0.05 max | 1.2 max | 0.10 max | 0.1 max | 0.10 max | 0.15 max | Rest |

| 5052 | 0.25 max | 0.4 max | 0.1 max | 0.10 max | 2.2-2.8 | 0.15-0.35 | 0.10 max | 0.15 max | Rest |

| 6061 | 0.4-0.8 | 0.7 max | 0.15-0.4 | 0.15 max | 0.8-1.2 | 0.04-0.35 | 0.25 max | 0.15 max | Rest |

chemical properties is valuable — they determine corrosion resistance, weldability, and strength. For instance, the inclusion of magnesium (Mg) in 5052 enhances corrosion resistance for marine environments while silicon (Si) promotes strength in 6061.

Why Opt for a 1.5mm Aluminum Sheet?

- Optimal Strength-to-Weight Balance: Thickness gives a rigid feel while allowing lightweight build-up.

- Economic Material Usage: Saves cost due to minimal material waste compared to thicker sheets when used appropriately.

- Versatile Tempering Options: Allows application in both malleable and value-engineered high-strength domains.

- Wide Industrial and Artistic Use: From reflector panels to enclosure cases and fragile aerospace parts — this gauge is frequently chosen to evade unnecessary heaviness yet preserve durability.

- Excellent Surface Enhancement: Suitable for anodizing or coating when aesthetics are required on functional items.