Double Layer UV Ink Resist Thermal CTP Plate

Double Layer UV Ink Resist Thermal CTP Plate: A Practical, Modern Pressroom Upgrade

In many commercial print shops, the phrase “UV-capable” used to mean compromise: slower plates, stricter handling, and a constant worry about plate wear under aggressive UV inks. Double layer UV ink resist thermal CTP plates change that equation completely.

Instead of being a niche, specialized option, they are becoming the new baseline for printers who handle both conventional and UV-curable jobs on the same press and need stability, speed, and long plate life.

What “Double Layer UV Ink Resist” Really Means

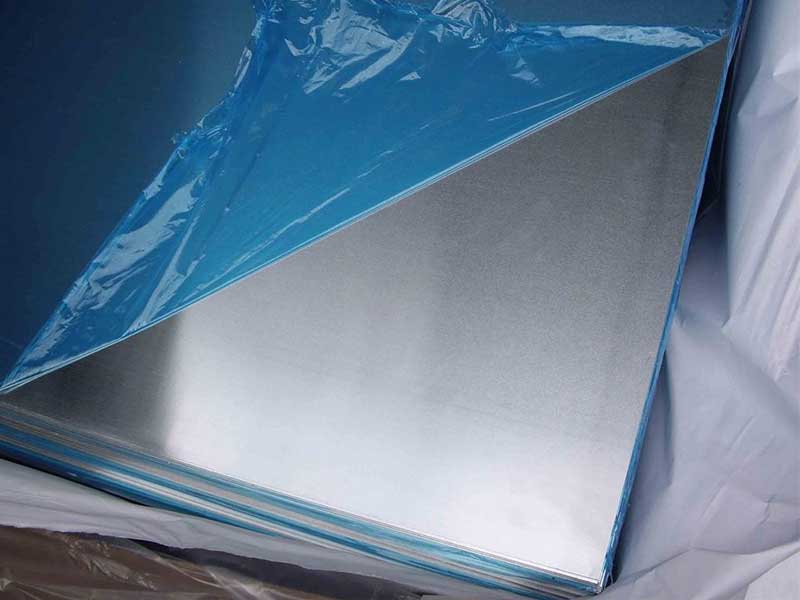

At first glance, a double layer UV ink resist thermal CTP plate looks like any other thermal offset plate. The difference is in the coating stack:

- Base: high‑grade aluminum, mechanically and chemically grained, anodized

- Undercoat: a functional layer that bonds tightly with the oxide film and stabilizes dot formation

- Topcoat: UV‑resistant imaging layer designed to withstand high‑energy UV inks and washes

Think of the second (top) layer as an armor plate for the image area. While the undercoat focuses on fine dot structure and consistent exposure behavior, the top UV‑resist layer is tuned to fight swelling, softening, and chemical attack from:

- High‑reactivity UV inks

- Fast-drying oxidative inks with strong solvents

- Aggressive fountain solutions and plate cleaners

By separating the roles of the two layers, plate manufacturers can improve both imaging precision and on-press durability instead of sacrificing one for the other.

Why Thermal CTP Still Matters

Thermal CTP technology remains the most popular for mid-to-high volume commercial printing for good reasons:

- Stable dot reproduction with minimal daylight sensitivity

- Excellent repeatability from plate to plate and job to job

- Strong compatibility with automated loading, punch-bend, and online processors

A double layer UV ink resist thermal plate integrates seamlessly into most 800–830 nm thermal CTP workflows. Typical imaging conditions include:

- Laser wavelength: 800–830 nm (infrared thermal diode)

- Energy sensitivity: around 90–120 mJ/cm² (depending on model and process)

- Screening support: AM up to 250–300 lpi; FM/stochastic 20–25 µm

- Plate setters: compatible with major brands (Kodak, Screen, Heidelberg, Agfa, etc.)

In many shops, no change to the CTP device is needed; only exposure energy, plate curve, and processing parameters are fine‑tuned during adoption.

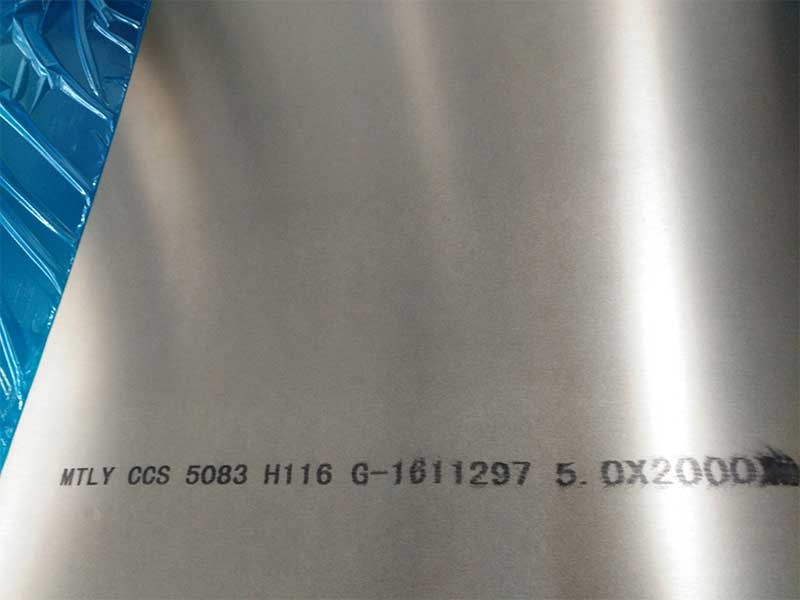

The Aluminum Core: Alloy, Temper, and Surface

The unsung hero of every good CTP plate is the aluminum substrate. For double layer UV ink resist plates, the metal foundation must handle long runs, tight clamping, and repeated bending without cracking or dimensional drift.

Common features of a quality substrate include:

- Alloy: typically Al-Mn or Al-Mg series (e.g., AA1050/AA1060 or equivalent)

- Temper: H18 or H19 (work-hardened) for stiffness and scratch resistance

- Thickness: usually 0.15–0.30 mm for sheetfed; 0.28–0.40 mm for web presses

- Flatness tolerance: controlled to ensure fast, reliable mounting and register

The aluminum surface undergoes a multi-step treatment:

- Mechanical graining or electrochemical graining

- Anodizing to form a durable Al₂O₃ oxide layer

- Sealing or post-treatment to adjust hydrophilicity and coating adhesion

This oxide film is critical: it anchors the double-layer coating and defines water-holding behavior in non-image areas. A uniform, fine-grained anodic layer gives sharper dots and less toning, especially on long runs with fast UV inks.

Typical Product Parameters at a Glance

While specific values vary by manufacturer, a modern double layer UV ink resist thermal CTP plate often delivers:

- Resolution capability: up to 1–99% dots at 200–250 lpi

- Run length:

- Up to 250,000 impressions with standard inks

- Up to 100,000 impressions with UV-curable inks

- Higher runs possible with optimized press conditions

- Compatibility:

- Sheetfed and web offset

- Alcohol and alcohol‑reduced dampening systems

- Conventional and UV inks

- Processing:

- Developer type: alkaline or neutral thermal plate developer

- Development time: 20–35 seconds at 22–26 °C (in automatic processor)

- Regeneration: automatic replenishment to maintain clean, stable baths

These numbers are not just labels; they define how confidently you can schedule a UV-heavy job on a Monday and still depend on the same set of plates to finish a reprint on Friday.

Implementation Standards and Quality References

Consistent performance relies on adherence to international and internal standards. A robust double layer thermal CTP plate program usually aligns with:

- ISO 12647 series: for process control in offset printing

- ISO 15930 (PDF/X): ensuring stable digital workflows that match plate behavior

- ISO 9001: quality management for plate production

- ISO 14001: environmental management for coating and processing chemistry

Manufacturers also define stricter internal standards for:

- Surface roughness (Ra/Rz) of grained aluminum

- Oxide weight and uniformity of the anodized layer

- Coating weight and thickness of each imaging layer

- Adhesion strength between layers and metal

For the customer, these invisible controls result in very visible benefits: fewer remakes, reduced need for on-press corrections, and reliable behavior across batches.

The chemistry behind a double layer UV ink resist plate is carefully tuned so that one layer focuses on imaging, while the other focuses on survival under harsh pressroom conditions.

Below is an example-style table describing typical chemical and performance-related properties. Values are illustrative and vary by supplier, but the categories reflect what matters in real use.

| Property | Typical Characteristic | Practical Impact |

|---|---|---|

| Imaging layer type | Negative‑working, IR‑sensitive polymer system | Stable thermal exposure and processing |

| UV resistance of top layer | High resistance to 365–400 nm UV spectrum | Less swelling, longer life with UV inks |

| Alkali resistance | Good in pH 10–13 developer environment | Clean development, sharp non-image areas |

| Solvent resistance | Resistant to common press solvents and washes | Reduced image loss during blanket/roller cleaning |

| Adhesion to aluminum oxide | Strong chemical bonding to anodic layer | No flaking or lifting on long runs |

| Hydrophilicity (non‑image area) | Stable water film, low affinity to ink | Fast roll-up, minimal scumming |

| Dot gain behavior | Low, predictable dot gain in mid-tones | Easier curve calibration; better highlight detail |

| Storage stability | 12–24 months under dry, dark conditions | Consistent plates over extended inventory cycles |

| Batch variation control | Tight tolerances on coating weight and sensitivity | Same exposure and processing settings job to job |

Behind each of these properties lies a set of polymer binders, UV‑stabilizers, dyes, and crosslinking agents carefully balanced so that the plate images easily but does not overreact to heat, UV, or pressroom chemistry.

On-Press Behavior: The Real Test

From the operator’s point of view, a double layer UV ink resist plate proves its worth not in the lab, but on the press floor. Typical benefits include:

- Faster roll-up: plates come up to color quickly, wasting fewer sheets

- Clean non-image areas: less toning and scumming, even on wide-format presses

- Stable highlights: fine dots hold longer on tough papers and UV jobs

- Reduced plate cracking: strong aluminum temper and coating flexibility support multiple bends and high clamp pressures

For mixed fleets where some towers run conventional inks and others run UV, the same plate type can often serve both, simplifying inventory and training.

Where These Plates Make the Most Difference

The advantages of double layer UV ink resist thermal CTP plates are most visible in demanding environments:

- High-volume commercial plants combining conventional and UV jobs

- Packaging printers using UV, hybrid, and specialty inks on carton board

- Web offset operations running at high speed with abrasive papers

- Trade shops that need to guarantee performance regardless of the customer’s press chemistry

In each case, the combination of a hardened aluminum base, optimized temper, robust oxide layer, and specialized dual coating offers a margin of safety and consistency that a single-layer plate often cannot match.

A Practical Upgrade Path

For printers already using thermal CTP, moving to a double layer UV ink resist plate is usually straightforward:

- Confirm wavelength and energy compatibility with the existing CTP engine

- Run a controlled test with standard and UV jobs side by side

- Adjust exposure energy, plate curves, and processor settings once, then lock them in

Most shops then discover that they can standardize on one plate type for the majority of their offset work, simplifying purchasing and reducing operational complexity.

Double layer UV ink resist thermal CTP plates are not just a chemical refinement; they represent a more realistic answer to how modern print is actually produced: fast, mixed-mode, often UV-heavy, and under constant pressure to be right the first time. By paying attention to alloy choice, tempering, oxide film, coating architecture, and chemical robustness, they deliver plates that behave predictably from prepress to press — which is exactly what a modern offset workflow needs.

https://www.aluminumplate.net/a/double-layer-uv-ink-resist-thermal-ctp-plate.html